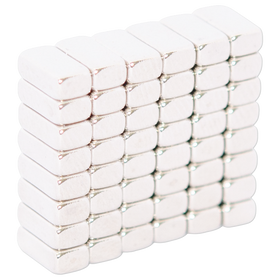

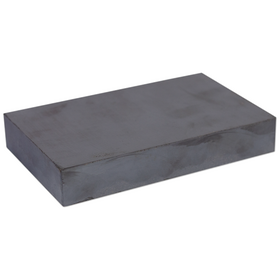

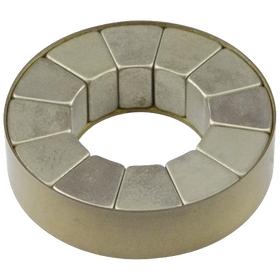

Neodymium Block Magnet - 10mm x 5mm x 5mm | N45

Same Day Dispatch

Order before 1pm to qualify for same day dispatch.

This Neodymium block magnet weighs 0.01kg and has a pull force of 2.71kg. Gauss 6590, Grade N45. It is 5mm in width, 10mm in length and 5mm in height and its direction of magnetisation is through height.

Neodymium magnets have changed the world. It may seem unlikely that a Rare Earth magnet like this Neodymium block magnet weighing just one gram plays a part in technical evolution – but it's true. These tiny, power-packed magnets have transformed industries, are helping us move towards greener renewables and reduce household costs. They just make things work better.

Because Neodymium magnets are compact and light but can still punch out stronger magnetic fields than other types of magnets, they have transformed a multitude of consumer products. Electronic devices, such as our mobile phones, laptops, microphones, audio equipment – are small, light and convenient because they have Neodymium magnets producing such strong, reliable magnetic power.

The range of applications for Neodymium block magnets is astounding – they're used to generate energy in cordless power tools, DC electric motors and generators and to produce sound in audio equipment like microphones and speakers. Neodymium magnets can allow for considerable energy savings by delivering a permanent magnetic force for power generation combined with electromagnetic fields. The power generated from electric motors using permanent Neodymium magnets can reduce costly mains electric power demand and reduce the drain on battery capacity for electric and hybrid vehicles, electric bicycles, scooters and many other battery-powered modes of transport. These Rare Earth block magnets weigh less than one gram each, about the size of a raisin, and yet they have changed our world.

Typical Physical Properties

NB: Ranges are indicative for product category, please check individual products for specic values within that range.

Production Flow Diagram

Demagnetization Curves

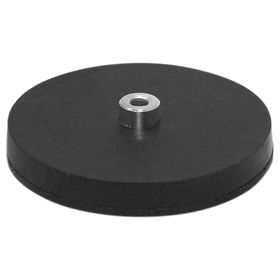

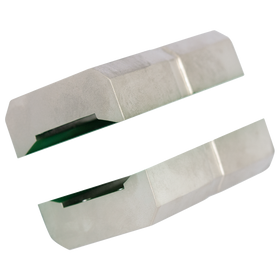

Surface Treatment

The most common coating for Neodymium magnets is Nickel + Copper + Nickel (Ni + Cu + Ni). This coating offers the magnet relatively good protection from corrosion and passive applications. If the magnet will be exposed to moisture or liquid then consider the use of an organic coating such as Epoxy. A hard wearing coating, Epoxy is suited to applications where the magnet will come under some friction or knocking.

Range and Tolerance

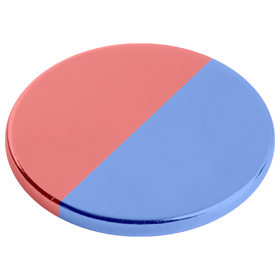

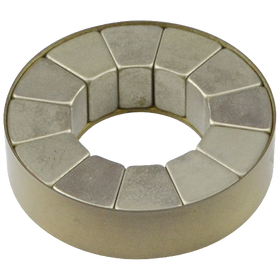

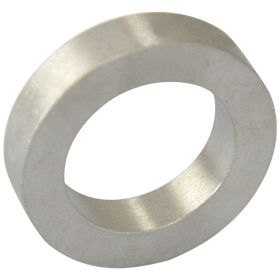

Magnets are readily available in Blocks, Discs, Cylinders & Rings. AMF Magnetics specializes in the supply of short-run prototype magnets including Arc Segments, various magnetic orientations etc. If you need a magnet size that we don't carry in stock, submit a Design-a-Magnet enquiry for a quote on your custom magnet design.

Magnetic Properties

Neodymium magnets are offered in several different grades. The first section N30-54 has an operating temperature of up to 80 degrees. Most of our stock only goes up to N38. The second section, denoted with the "M" prefix after the grade has an operating temperature 100 degrees. After this the grades are "H", "SH", "UH" & "EH". In order for the magnet to withstand a higher operating temperature, during production more of the raw material PrNd is incorporated as these elements have a naturally occurring resistance to high temperatures.

Returns Policy

If you are not entirely satisfied with your purchase, we're here to help.

We have a 30 Day Returns policy at Frenergy Magnets. You may return your item within 30 days of receiving it to receive a refund.

The product/s must be unused and in the same condition you received them in. Please contact us at info@frenergy.com.au to initiate the returns process.

The buyer is responsible for the cost of returning the order.