Workshop & Warehouse

Magnetic attachment and the use of magnetic industrial equipment has become a widely adopted practice for industries of all kinds. Food processing and manufacturing companies have implemented industry-specific magnetic systems to ensure product quality and consumer safety for many years. Innovative manufacturing techniques and production processes also increasingly use magnetism in their operation.

Frenergy supplies large industrial strength magnets and magnetic products that are suitable for the Workshop, Factory, Warehouse and many other commercial premises. Warehouses, Factories and Processing Plants use a range of magnetic products on a daily basis to retrieve foreign metal objects, separate out metal contaminants, organise storage areas and keep work areas clean and free of potentially hazardous metal waste.

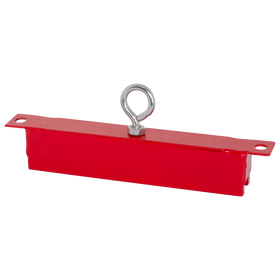

Large industrial strength magnetic apparatus, lifting equipment and magnetic collection devices are available to help keep your work area operating in an effective and efficient manner while also promoting safe work practices.

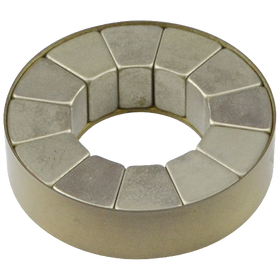

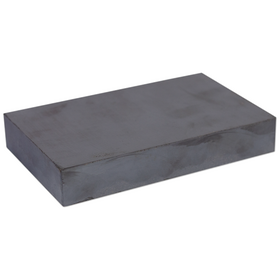

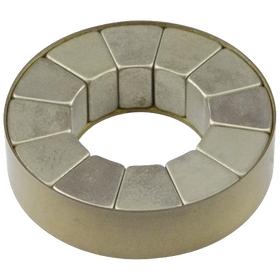

As a prominent supplier of powerful Neodymium magnets and other magnetic products and devices, Frenergy stocks industrial Separator Bar magnets for foodstuff filtration and heavy-duty stainless steel grate magnets that are suitable for commercial food manufacturing. We also have a range of heavy-duty retrieval and lifting magnets.

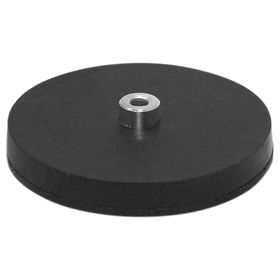

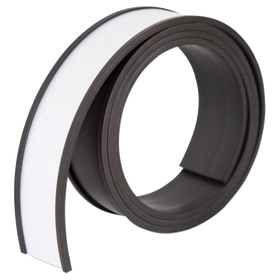

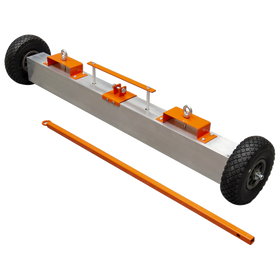

Industrial fastening magnets and clamping magnets for commercial or domestic use can be found in the Mounting Pot magnet category. Magnetic identification labels can be attached to steel racking to help locate products and their storage spaces more accurately and efficiently. Industrial magnets that hang from Forklift tynes and Magnetic Sweeping devices on wheels allow dangerous metal off-cuts to be removed from the factory floor and disposed of safely.

Magnetic Ball Joint apparatus are commonly used to attach surveillance and security equipment in a reliable, yet easy to adjust or remove manner

Magnetic closure latches, long-handled Swarf Pickup Tools, magnetic water purification devices and industry-specific custom made magnetic assemblies are all part of the Frenergy product range and services.

FAQ

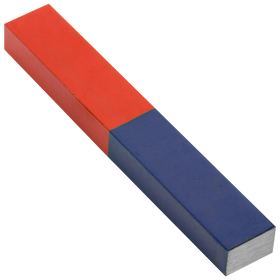

How are industrial magnets made?

Industrial magnets mostly utilise the enormous strength of Neodymium rare earth magnetic material. Industrial magnets are often made as a magnetic assembly with a heavy-duty protective covering to protect the magnet from damage. They are designed to withstand impact damage and are also able to support heavyweights in a commercial environment. Large Neodymium magnets inside a Magnetic Lifter means these powerful tools are able to support extremely heavy weights up to 237kg!

How do industrial lifting magnets work?

There are two magnetic products that are suitable for industrial-strength lifting. Frenergy supplies Lifting Magnets that contain permanent Neodymium magnets in an arrangement that exerts the strongest possible magnetic field strength. Although the field is strong, it is not particularly deep or penetrating, so when the release lever is applied, an air gap is created between the ferrous steel surface and the magnetic lifter. This physical distance causes the magnetic field to be ineffective and the steel product is released from its magnetic hold. The other type of lifting magnet uses an electrically generated magnetic field that releases its hold when the electrical power source is switched off. These are known as Electromagnets and use copper wire coils and electric current to generate magnetic power.

What are the industrial uses for magnets?

Many industrial and commercial enterprises use magnets in their daily operations. Businesses that deal in metal and steel products and the associated industries use strong industrial magnets for material handling and lifting. Magnetic welding clamps, pickup tools and magnetic sweepers are important pieces of equipment for many workshops and factories. Mine sites use industrial magnetic fasteners with hooks and eyelets to hang cables and lighting equipment. These sites find Mounting Pot magnets are strong and can be quickly attached and relocated when needed. Magnetic latches and equipment holders are also commonly used in workplaces and industrial locations of every kind.