Flexible Magnetic Rubber

Rubberised magnetic material is used to make cost-effective products that have practical applications in educational, office and workplace environments. These flexible magnetic products in their various forms are valued for their affordability, durability and versatility.

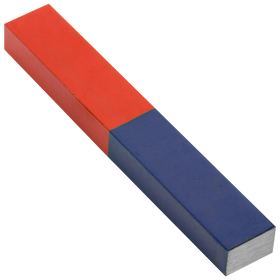

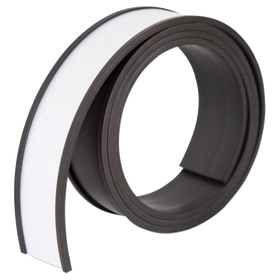

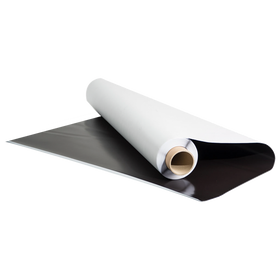

Flexible magnetic products have been developed as an innovative solution to some of the impractical issues associated with conventional hard and rigid magnets such as disc and block-shaped magnets. Flexible magnets are a low strength option that is easy to move around on office and classroom whiteboards and are a safer option for school-based activities involving children. Frenergy has a large range of popular and useful flexible magnetic rubber products that offer great value for money. Flexible magnetic sheet products are used in offices, schools, signage companies, marketing agencies, warehouses and creative homes and workshops around the country. Examples of flexible magnetic sheet and tape products include coloured magnetic strips in a range of lengths and widths, adhesive-backed flexible tapes, magnetic labels in pre-cut or custom sizes, printable magnetic paper and flexible coloured magnetic sheets in large 30-metre rolls.

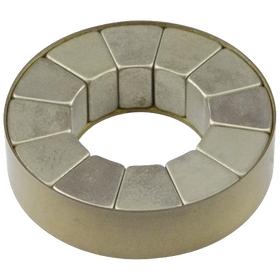

For the majority of flexible magnetic rubber products, Ferrite magnetic powder makes up the magnetic component. A few rare earth flexible tapes contain Neodymium powder that provides enormous strength but is far less cost-effective and more suited to commercial or industrial applications. The inexpensive Ferrite material in powder form is combined with rubber to give the magnets their flexibility. The end product is relatively weak in terms of magnetic strength because of the large amount of non-magnetic rubber content but the flexible nature, low cost and ease in which the flexible sheet-form magnet can be cut and shaped add real value and convenience to this type of product.

Use Flexible Magnetic Rubber to make magnetic signs and labels

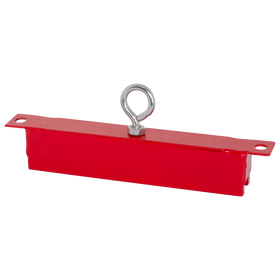

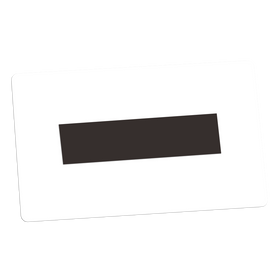

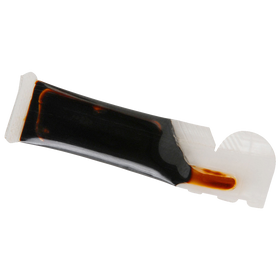

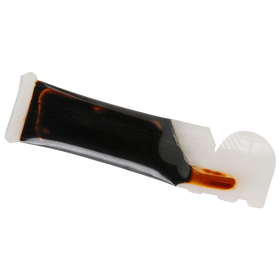

Some flexible magnets have glossy PVC coatings that are rewritable using a non-permanent marker and are suitable for magnetic whiteboard use in classrooms and offices. The flexible magnetic sheet which can be purchased by the metre or in large rolls is easily cut to make magnetic labels in any size or colour. These flexible labels can be handwritten onto or put onto the back of a printer label and are ideal for labelling warehouse shelves or identifying metal storage racks. Flexible magnetic rubber sheeting is also used to create the popular adhesive-backed magnetic Patches and Tabs. These small rectangular flexible magnets are used throughout the commercial printing industry to convert paper or cardboard printed material into magnetic refrigerator-compatible advertising for both small business operators and large established companies. These low-cost flexible magnets also appeal to home hobbyists who want to add a magnetic feature to their projects.

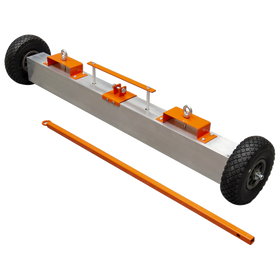

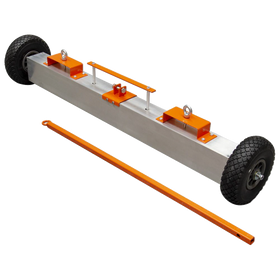

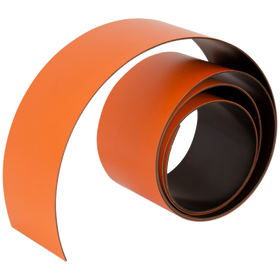

Make Safety a priority in the workplace with magnetic Hazard Warning tapes

Long magnetic strips with bright reflective coatings are another type of flexible magnet that is popular with business owners and workplace managers. Most business premises have a range of steel surfaces in the form of shelves, cabinets, doors, fences, machinery and equipment. Frenergy has brightly coloured, reflective magnetic warning tapes that are flexible and attach magnetically to these surfaces and are ideal for alerting staff or customers to damaged areas, spills or trip hazards.

Frenergy has magnetic products for the office

From see-through magnetic photo pockets, that keep important information or photographs protected and displayed on your fridge or filing cabinet, to magnetic business or promotional advertising and large rolls you can cut to any size, the Frenergy range of products can cover every situation. Magnetic warehouse labels, A4 and A3 printable magnetic paper, rolls of magnetic sheeting or flexible magnets with their own peel-away adhesive backing can be purchased with confidence on the secure Frenergy online store for free standard Australia wide shipping for orders over $50.

Frequently Asked Questions

How are flexible magnets made?

Flexible magnets are made from a compound of Rubber and Ferrite magnetic material in powdered form that is then combined and processed into thin magnetic sheets or thick flexible tapes. The sheets are then sold in large bulk rolls, short 1 metre lengths or thin magnetic strips and tapes.

How to cut a magnetic sheet?

Flexible magnets are designed for applications where the magnetic material needs to be cut to a particular length, size or shape. A straight edge ruler and box cutter knife are ideal for cutting flexible magnetic sheets but scissors are also suitable and are especially useful for curved or round surfaces.

Do flexible magnets stick to each other?

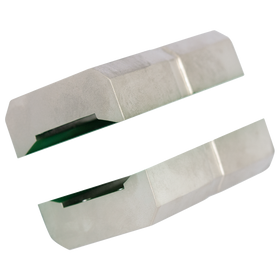

The Magnafix range of flexible tapes is a specially designed magnetic tape that is sold in matching Part A and Part B sets. The paired tapes bond together strongly with opposite poles and are ideal for retrofitting double glazing to windows via the convenient adhesive backing on each tape.

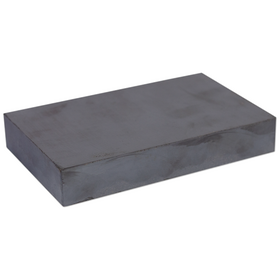

With most other flexible magnets, only one surface is magnetic and capable of bonding to ferrous metal. That same magnetic surface will also bond to a similar one on another flexible magnet but there are few applications where this type of bond is of any practical use. Most flexible magnets are not designed for applications that involve bonding or holding two surfaces together. The thin flexible nature and high rubber content in flexible magnetic products lead to lower magnetic power when compared to solid block or disc magnets. Flexible magnets bond to ferrous metal surfaces or another magnetic material with typically weak or moderate strength. The benefits of these rubberised types of magnets are mainly found in their affordability, versatility and flexible nature.