Permanent Magnets - Other

There are several types of permanent magnets including Neodymium, Alnico, Ferrite (ceramic magnets), and Samarium-Cobalt. The term permanent magnet simply means that they are able to maintain a magnetic field indefinitely. Unless they are demagnetised through the use of electric current, a strong magnetic field or high temperatures they will typically retain their magnetic strength forever.

Permanent Magnetic Properties

The term Permanent Magnet describes all types of magnets, excluding Electromagnets. The magnetic field of a Permanent Magnet is always present and cannot be switched off. Permanent magnets operate independently and provide magnetic hold without the need for an external power source. Electromagnets, on the other hand, rely on an AC or DC electric power source to create a magnetic field. The field only operates when the power is switched on and for this reason, electromagnets are regarded as non-permanent.

Although the magnetic field of a Permanent magnet is perpetual, it can decrease or weaken if the magnet is damaged, dropped, or broken. High temperatures and corrosion can also cause the magnetic field to fail. Depending on the circumstances, this failure of the magnetic field can be permanent, or in some cases, the field may return over time. The coercivity value of a magnet determines how resistant it is to demagnetisation from excessive temperature or another strong ferromagnetic force. Demagnetisation from heat exposure can occur and is often permanent because it damages the alignment of the magnetic molecules inside the magnet.

The Permanent Magnet group of magnets includes the Rare Earth Neodymium and Samarium-Cobalt magnets, both of which are made from rare earth alloys. Ferrite (Ceramic) and Alnico magnetic products are also in the permanent magnet group. Each of these magnet types has physical properties and characteristics that can be used to suit different situations, applications, and environments.

Types of Permanent Magnets

Neodymium has properties that make them highly suitable for specialized applications where magnetic strength is the most important requirement. Neodymium magnets are also commonly referred to as Rare Earth magnets and they are the strongest permanent magnets on the market. Neodymium permanent magnets have enormous holding power for their size but are limited to 80℃ operating temperatures. Above this level, their magnetic power dwindles as the temperature continues to rise. Their shiny nickel-based coating protects the magnet to some extent but they become susceptible to corrosion over time.

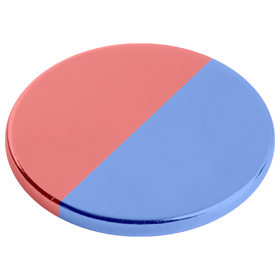

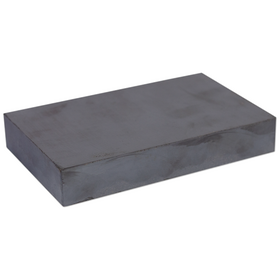

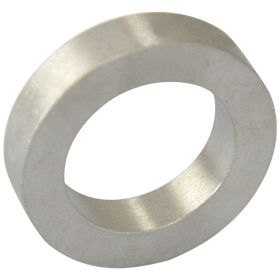

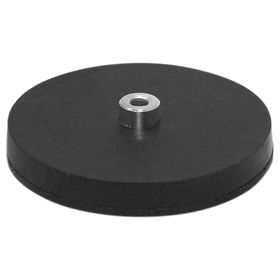

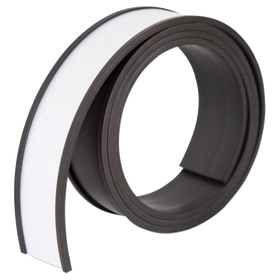

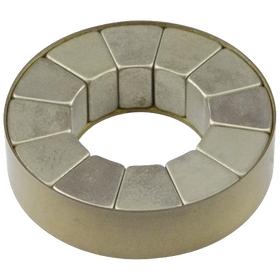

Ferrite magnets, otherwise known as ceramic magnets, have a wide field and are relatively lightweight. They are also highly resistant to corrosion which can be extremely helpful in outdoor environments or where exposure to corrosive elements is expected. Ferrite magnets are also the most affordable of the magnetic materials but are considerably weaker than Neodymium magnets. Ferrite(Ceramic) magnets are also a type of permanent magnet. The powder form of this grey, chalky, magnetic material is combined with rubber to make the popular flexible magnetic sheeting and magnetic signage and labeling products. Hard-form Ferrite magnets in the shape of blocks, discs, and rings are brittle and can break easily but are also highly resistant to corrosion and also very affordable. This type of magnet can provide an effective and very economical magnetic solution for many applications when the magnet is handled correctly or a protective cover is used.

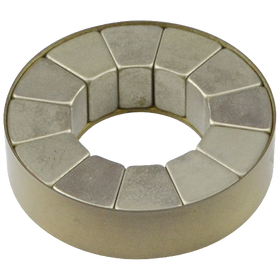

Samarium-Cobalt magnets are resistant to oxidation and temperature fluctuations and this type of magnetic material is used in applications where high temperatures (over 80℃), humidity, or marine environments are present. Samarium-Cobalt permanent magnets have wide-ranging temperature stability and can remain operational at cryogenic temperatures as well as high-temperature environments above 200℃. This rare earth material has considerable magnetic strength and is extremely resistant to corrosion and demagnetisation. The inclusion of Cobalt in the alloy makes these magnets more expensive to buy.

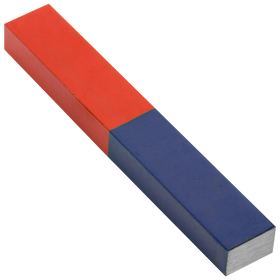

Alnico magnets are created from an aluminum, nickel, and cobalt alloy and are often valued for their conductive properties. Unlike other magnetic materials, Alnico magnets are also able to operate at extremely high temperatures. Alnico permanent magnets are relatively weak in terms of magnetic power but they have superior temperature resistance (coercivity) and can remain active in temperatures up to 500℃ before demagnetisation occurs. The aluminium content in the Alnico alloy also ensures they have outstanding corrosion resistance. Alnico magnetic material also benefits from being electrically conductive.

Customer Questions

How do permanent magnets work?

Materials that qualify as Permanent magnets can be magnetised so that the field remains active for the life of the magnet. Some ferromagnetic substances, such as iron can be magnetised with a magnetic field but with time the field diminishes. Hard ferromagnetic materials, including Ferrite and Rare Earth alloys, have a molecular structure that is more easily aligned with a magnetic field. The crystalline structures in these magnetised materials align more uniformly and create a magnetic flow between the North and South poles that is highly magnetic and also permanent.

What are permanent magnets made from?

Permanent magnets are made with ferromagnetic materials or alloys with a molecular structure that conforms and aligns strongly once a magnetic field is applied. This structural transformation makes the material become magnetic and it will remain in this state permanently. Ferrite magnets contain iron oxide with barium or strontium carbonate. Neodymium magnets use iron and boron in an alloy and are often coated with nickel for durability. Some permanent magnets are made with aluminium, nickel, and cobalt alloy (Alnico) and others use a Samarium-Cobalt alloy.

Can a permanent magnet lose its magnetism?

Demagnetisation of permanent magnets can sometimes occur in certain conditions or unusual circumstances. Magnets subjected to high heat environments (above the magnets Curie temperature) can cause the crystalline structure of the magnetic material to misalign or become deranged and thus lose its magnetic power. When strong external magnetic fields are applied to a magnetic material, a similar impact to the crystalline arrangement can occur and cause the magnetic energy output to drop significantly or completely disappear. Harsh impact or structural damage also disrupts the magnetic alignment with similar consequences. Using the appropriate magnet for the application and operating conditions will ensure demagnetisation is a rare occurrence.