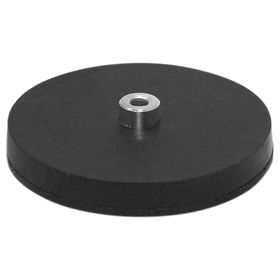

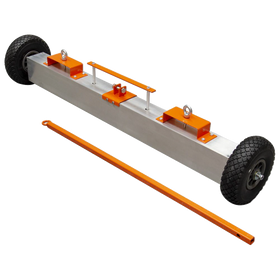

One Lifter model (PML) is designed to lift flat sheet metal and the other Pipe Lifter model (PMLR) makes it possible to lift round steel products such as steel pipes and tubes.

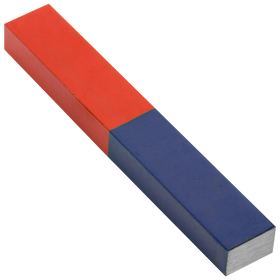

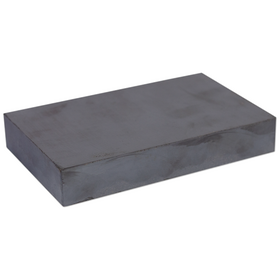

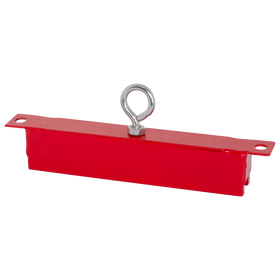

The standard PML models have a completely flat attaching surface that ensures strong attachment across the entire magnetic surface. This strong and direct bond produces a higher weight lifting capacity for flat steel products.

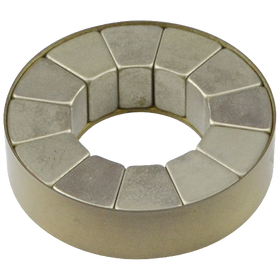

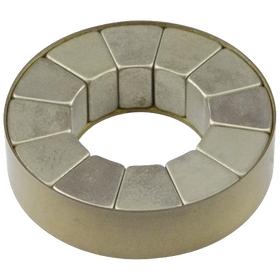

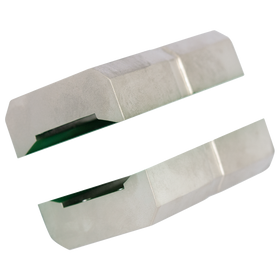

In contrast, the PMLR model has a more angled contact surface which enables it to bond more securely and more effectively with round-shaped steel because of the more suitable contact surface area. Please note that the lifting capacity of the PMLR model halves when lifting round steel products.

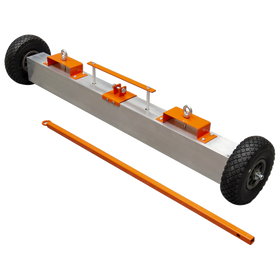

Frenergy has Permanent Magnet Lifters available in a range of sizes and lifting capacities. One of the benefits of both the PML and PMLR models is that they have the handy, manually operated release lever. The lever disengages the magnet and releases the steel product safely once it is in the right location. This reduces the need for traditional slow and awkward block and tackle hoisting.

Direct contact between the Lifter and the steel is crucial to the performance of all Magnetic Lifters and any gap that results from paint, coverings or wrapping of the steel will significantly reduce the magnet’s lifting capacity. Frenergy has a range of magnets that can really to improve safety and productivity levels in your workshop or factory. Visit the Magnetic Tools & Equipment category to find out more!