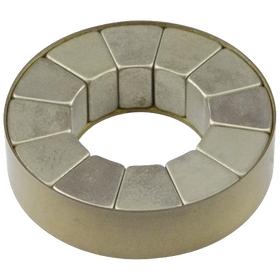

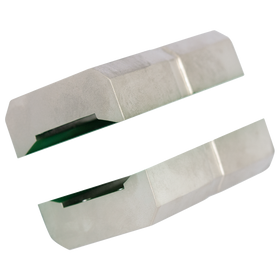

Magnetic Separator Filter Bar D25mm x 300mm | M6 Thread | 10K Gauss

Same Day Dispatch

Order before 1pm to qualify for same day dispatch.

Magnetic Product Description:

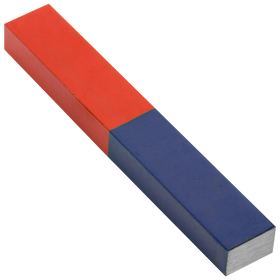

This Magnetic Separator Bar or Tube magnet has a 300mm length, a 25mm width and a 6mm thread for easy fitting and attachment. Made with a strong neodymium magnet encased in stainless steel

Uses for our separator bar tube magnets:

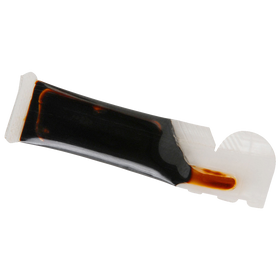

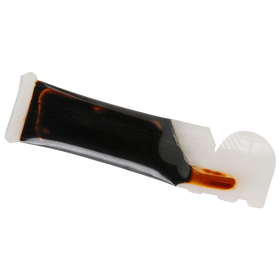

- Metallic foreign object debris (FOD) finds its way into food and beverage manufacturing processes through the raw materials of primary production.

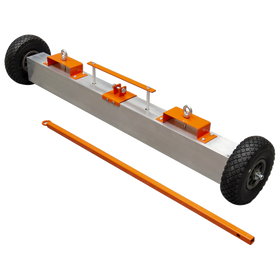

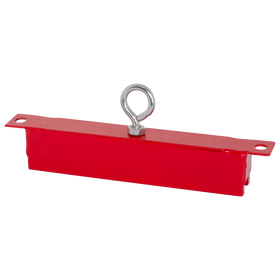

- Magnetic Separator Bars at all stages of processing remove metallic contamination that originates on farming land, silos, and feedlots in the form of wire, nails, screws, bolts, washers and clips.

- Metal fragments of broken machinery must be arrested and by suspending Separator Magnets strategically above or below conveyer belts or at the opening to Hoppers or Storage Bins most of the contaminant material can be safely removed.

- As well as compliance with Food Authority legislation, vigilant decontamination monitoring reduces the incidence of recalls, reputational damage, and lawsuits for damages and compensation.

- Avoiding costly downtime due to equipment failure is another benefit that Magnetic Separation provides.

- This separator bar is 300mm in length and is ideal for collecting unwanted swarf and metal pieces that can contaminate industrial processes.

Returns Policy

If you are not entirely satisfied with your purchase, we're here to help.

We have a 30 Day Returns policy at Frenergy Magnets. You may return your item within 30 days of receiving it to receive a refund.

The product/s must be unused and in the same condition you received them in. Please contact us at info@frenergy.com.au to initiate the returns process.

The buyer is responsible for the cost of returning the order.