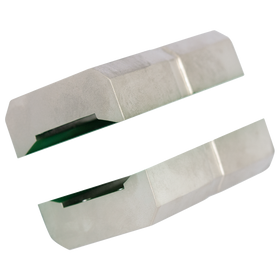

Neodymium D42 Hose Clamp P-Clip Magnet | Neoprene ID16mm dia. (68kg)

Same Day Dispatch

Order before 1pm to qualify for same day dispatch.

Neoprene-coated steel support clamps with powerful pot magnet.

These lightweight neoprene-coated steel support clamps are designed to support hose where long runs are necessary.

This clamp not only provides a cleaner installation, it prevents damage, exposure and chafing.

The neoprene lining will withstand high ambient temperatures.

Clamp ID Closed : 0.63 inch

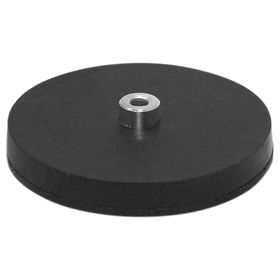

Pot Magnet Description:

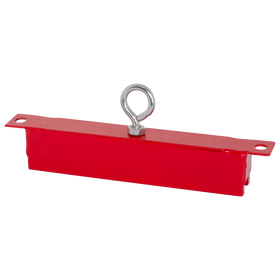

Magnetic holders are used for attaching a variety of metal items.

The product consists of a small metal cup containing a neodymium rare earth magnet with female thread.

Just attach the magnet to the metal surface·

Organise your tools in a safe and secure manner·

Ideal for holding kitchen utensils, gardening, mechanical and handyperson tools·

Secures metal objects in place with easy removal or replacement·

Easy to install, easy to use practical magnetic product

Magnet's Endless Uses:

Magnetic holders/hooks are a very versatile product for hanging almost anything.

Magnetic holders/hooks attach to metal surfaces, are non-marking and design for easy removal.

No screws, nails or drills needed·

Ideal for hanging pot plants, tools, hats, keys, lights, paintings, wind chimes, displays etc.·

Can be attached either in horizontal or vertical positions·

Easy to attach and remove, easy to use practical magnetic product

IMPORTANT NOTES:

Magnets rated holding force is when contacted directly against mild steel 3mm thick or greater.

The theoretical holding force described is for horizontal holding (based on a min 3mm thick steel surface). If you position the magnet to the vertical, you should divide the holding force amount by 3. This is due to the the influences of gravity and reduced friction.

AVOID:

Please note that magnetic strength will be weaker if the item you are attaching to is alloy, stainless steel, Colourbond steel, painted, oily, rusty or bumpy.

Also, if the ferrous item your attaching to is thin, the magnet will be weaker too, i.e. foil or sheet metal

If something in between the magnets and the surface your attaching to (i.e fabric), the pull strength also will be lesser.

Typical Physical Properties

NB: Ranges are indicative for product category, please check individual products for specic values within that range.

Production Flow Diagram

Demagnetization Curves

Surface Treatment

The most common coating for Neodymium magnets is Nickel + Copper + Nickel (Ni + Cu + Ni). This coating offers the magnet relatively good protection from corrosion and passive applications. If the magnet will be exposed to moisture or liquid then consider the use of an organic coating such as Epoxy. A hard wearing coating, Epoxy is suited to applications where the magnet will come under some friction or knocking.

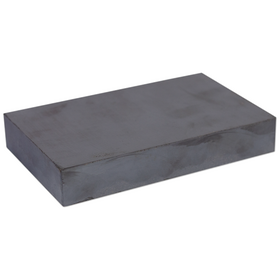

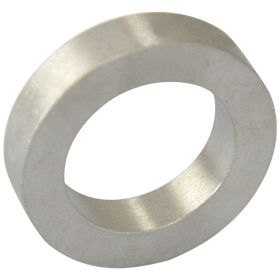

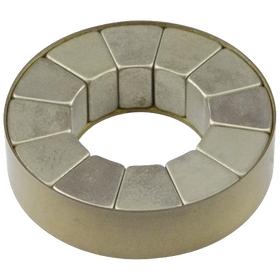

Range and Tolerance

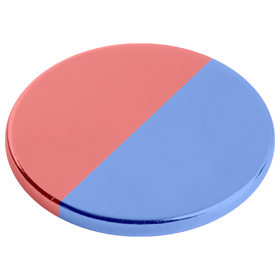

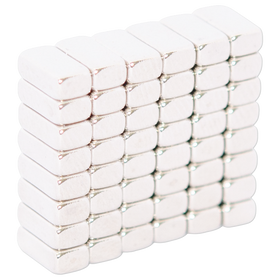

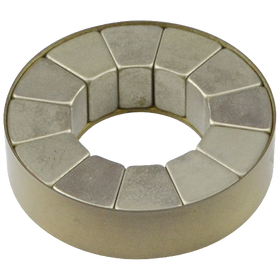

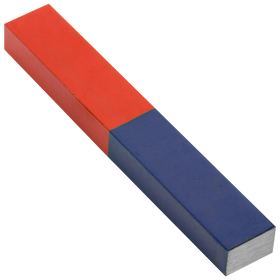

Magnets are readily available in Blocks, Discs, Cylinders & Rings. AMF Magnetics specializes in the supply of short-run prototype magnets including Arc Segments, various magnetic orientations etc. If you need a magnet size that we don't carry in stock, submit a Design-a-Magnet enquiry for a quote on your custom magnet design.

Magnetic Properties

Neodymium magnets are offered in several different grades. The first section N30-54 has an operating temperature of up to 80 degrees. Most of our stock only goes up to N38. The second section, denoted with the "M" prefix after the grade has an operating temperature 100 degrees. After this the grades are "H", "SH", "UH" & "EH". In order for the magnet to withstand a higher operating temperature, during production more of the raw material PrNd is incorporated as these elements have a naturally occurring resistance to high temperatures.

Returns Policy

If you are not entirely satisfied with your purchase, we're here to help.

We have a 30 Day Returns policy at Frenergy Magnets. You may return your item within 30 days of receiving it to receive a refund.

The product/s must be unused and in the same condition you received them in. Please contact us at info@frenergy.com.au to initiate the returns process.

The buyer is responsible for the cost of returning the order.