Neodymium Block Magnet – 2mm x 3mm x 1mm | N52 | Micro-Magnet

Same Day Dispatch

Order before 1pm to qualify for same day dispatch.

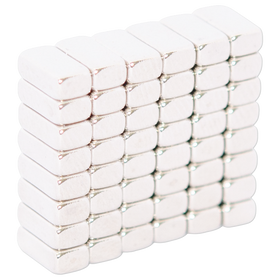

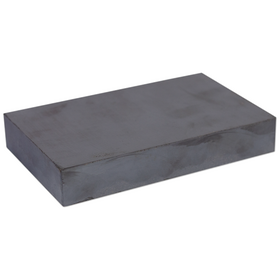

Experience impressive strength in a tiny package with this Neodymium Block Magnet – 2mm x 3mm x 1mm. Engineered from premium N52 grade neodymium, this micro-magnet delivers a surprisingly powerful pull force of 122 grams, making it perfect for precision applications where space is limited but high performance is essential. This product is identified by product code 22076.

Key Features:

Dimensions: 2mm (W) x 3mm (L) x 1mm (H)

Grade: N52 – the highest commercially available neodymium grade for maximum strength

Pull Force: 122 grams

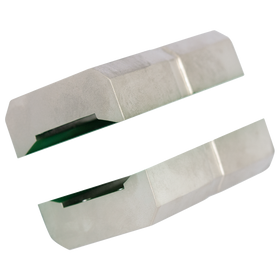

Coating: Nickel-Copper-Nickel triple layer for corrosion resistance and a smooth, durable finish

Shape: Rectangular block magnet with sharp edges and compact design

Tolerance: ±0.05mm

Benefits:

Exceptional Strength-to-Size Ratio – despite its tiny size, this micro magnet offers impressive holding power.

Durable Nickel Plating – provides protection against rust and wear, ensuring long-lasting reliability.

Compact & Versatile – ideal for use in small assemblies, electronic projects, and custom applications.

High Precision – engineered with tight tolerances for accuracy in delicate or technical installations.

Common Applications:

Electronics & Sensors: Micro-switches, circuit boards, and precision instruments.

Engineering & Prototyping: Compact magnetic solutions for innovative designs.

Crafts & DIY Projects: Model making, miniature builds, and custom projects requiring discreet strength.

Medical & Research Equipment: Laboratory instruments and scientific applications where precision is vital.

With its ultra-small footprint and maximum N52 magnetic strength, this block magnet is a go-to solution for projects that demand reliability, precision, and high performance in minimal space. Whether you’re working in electronics, engineering, crafts, or scientific research, this micro neodymium magnet delivers big results in a tiny size.

Typical Physical Properties

NB: Ranges are indicative for product category, please check individual products for specic values within that range.

Production Flow Diagram

Demagnetization Curves

Surface Treatment

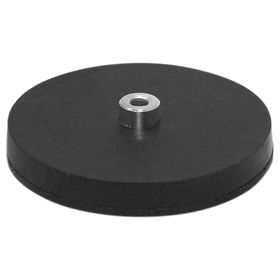

The most common coating for Neodymium magnets is Nickel + Copper + Nickel (Ni + Cu + Ni). This coating offers the magnet relatively good protection from corrosion and passive applications. If the magnet will be exposed to moisture or liquid then consider the use of an organic coating such as Epoxy. A hard wearing coating, Epoxy is suited to applications where the magnet will come under some friction or knocking.

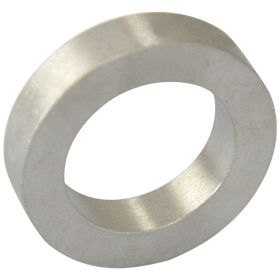

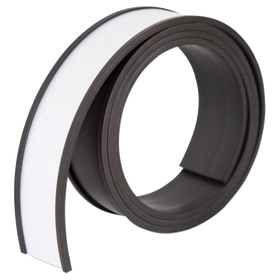

Range and Tolerance

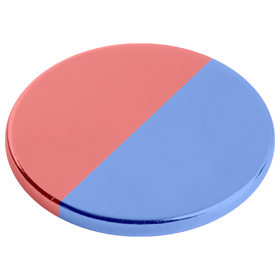

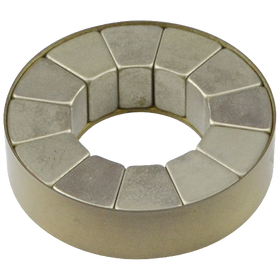

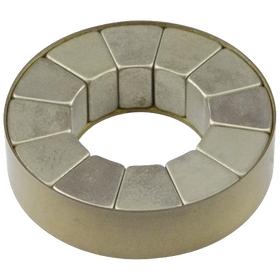

Magnets are readily available in Blocks, Discs, Cylinders & Rings. AMF Magnetics specializes in the supply of short-run prototype magnets including Arc Segments, various magnetic orientations etc. If you need a magnet size that we don't carry in stock, submit a Design-a-Magnet enquiry for a quote on your custom magnet design.

Magnetic Properties

Neodymium magnets are offered in several different grades. The first section N30-54 has an operating temperature of up to 80 degrees. Most of our stock only goes up to N38. The second section, denoted with the "M" prefix after the grade has an operating temperature 100 degrees. After this the grades are "H", "SH", "UH" & "EH". In order for the magnet to withstand a higher operating temperature, during production more of the raw material PrNd is incorporated as these elements have a naturally occurring resistance to high temperatures.

Returns Policy

If you are not entirely satisfied with your purchase, we're here to help.

We have a 30 Day Returns policy at Frenergy Magnets. You may return your item within 30 days of receiving it to receive a refund.

The product/s must be unused and in the same condition you received them in. Please contact us at info@frenergy.com.au to initiate the returns process.

The buyer is responsible for the cost of returning the order.