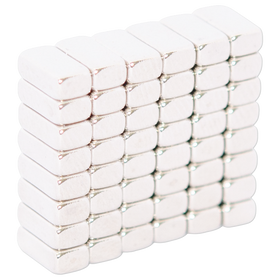

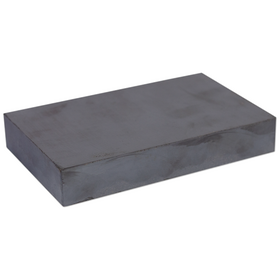

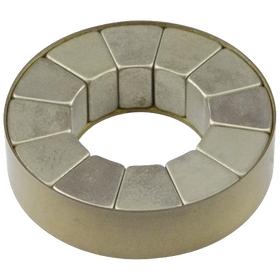

Neodymium Block Magnet - 40mm x 10mm x 10mm | N48

Same Day Dispatch

Order before 1pm to qualify for same day dispatch.

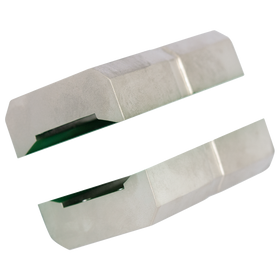

This Neodymium block magnet weighs 80 grams and has a pull force of 15.42kg. Gauss 6806, Grade N48. Its dimensions are 10mm in width, 10mm in height, and 40mm in length. Its direction of magnetization is through height.

Neodymium Block magnets have transformed how we live, the devices we use and had a huge impact on innovation in our high-tech world. You won't know they're there, but Neodymium magnets are in countless devices we use in everyday life, from our smartphones, laptops and audio devices to our cars, household appliances, our creative outlets in art and craft, even in medical devices that keep us alive. Neodymium Rare Earth magnets are little miracles.

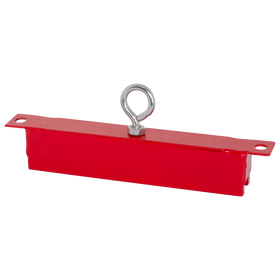

This nickel-coated Neodymium block magnet is super handy with a hefty pull force. Its square shape means this magnet can fit easily into corners where it can magnetically bind two surfaces together. That might be a frame, an electronic device, a door or container – any application requiring a strong, flat, permanent Neodymium block magnet. In electric motors, these Neodymium block magnets transform electrical power into movement, and are essential in countless appliances, devices and industrial systems, in commercial processes and in household products.

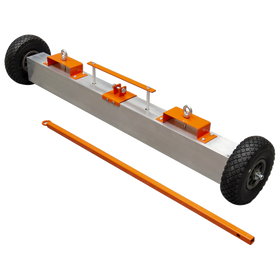

This relatively large Rare Earth block magnet has N48 Grade strength particularly suitable for domestic holding purposes. The long, narrow proportions of this bar-shaped magnet are also ideal for commercial applications, which can include magnetic filtration and separation, industrial clamping, magnetic retail signage or industrial metal swarf cleaning. With a holding force of over 15kg this silvery, nickel-coated block magnet will support most weights around the home.

Word of caution – this is a strong block magnet that can bind heavy objects to metal surfaces easily but can also crush or damage lightweight or delicate items, so handle with care.

Typical Physical Properties

NB: Ranges are indicative for product category, please check individual products for specic values within that range.

Production Flow Diagram

Demagnetization Curves

Surface Treatment

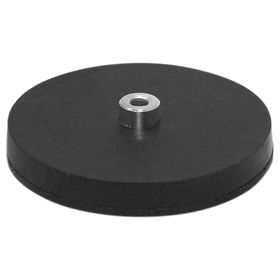

The most common coating for Neodymium magnets is Nickel + Copper + Nickel (Ni + Cu + Ni). This coating offers the magnet relatively good protection from corrosion and passive applications. If the magnet will be exposed to moisture or liquid then consider the use of an organic coating such as Epoxy. A hard wearing coating, Epoxy is suited to applications where the magnet will come under some friction or knocking.

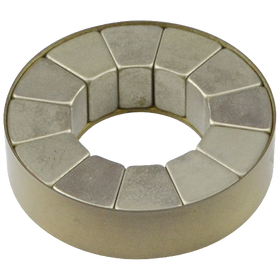

Range and Tolerance

Magnets are readily available in Blocks, Discs, Cylinders & Rings. AMF Magnetics specializes in the supply of short-run prototype magnets including Arc Segments, various magnetic orientations etc. If you need a magnet size that we don't carry in stock, submit a Design-a-Magnet enquiry for a quote on your custom magnet design.

Magnetic Properties

Neodymium magnets are offered in several different grades. The first section N30-54 has an operating temperature of up to 80 degrees. Most of our stock only goes up to N38. The second section, denoted with the "M" prefix after the grade has an operating temperature 100 degrees. After this the grades are "H", "SH", "UH" & "EH". In order for the magnet to withstand a higher operating temperature, during production more of the raw material PrNd is incorporated as these elements have a naturally occurring resistance to high temperatures.

Returns Policy

If you are not entirely satisfied with your purchase, we're here to help.

We have a 30 Day Returns policy at Frenergy Magnets. You may return your item within 30 days of receiving it to receive a refund.

The product/s must be unused and in the same condition you received them in. Please contact us at info@frenergy.com.au to initiate the returns process.

The buyer is responsible for the cost of returning the order.