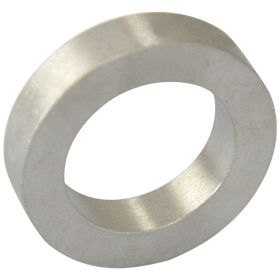

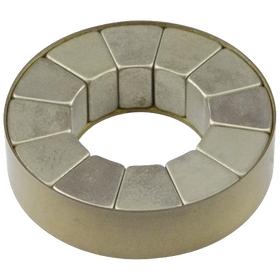

Neodymium Countersunk Ring Magnet OD22.5mm x H3mm | C/sunk Hole 4mm N45

Same Day Dispatch

Order before 1pm to qualify for same day dispatch.

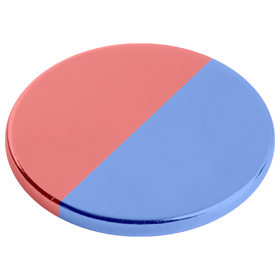

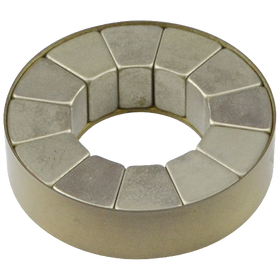

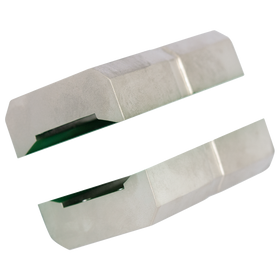

This Countersunk Neodymium Magnet has an outside diameter of 22.5 mm, an inner diameter of 4mm, a thickness of 3mm and a 90 degree countersunk shaft. This Nickel plated Rare Earth countersunk ring has a powerful N45 grade and a pull force of 4.42kgs.

The countersunk hole allows straightforward attachment to almost any material such as wood, plastic and masonry, to name just a few. Simple to attach with a flat head screw, the tapering screw head sits flush inside the countersunk magnet for seamless professional finish. These magnets can also be recessed into timber or plastic and secured with a countersunk screw for a permanent result without the need to use messy glue. Glue can perish or discolour with age however screws stay true, making them the ultimate fixing solution.

Countersunk magnets are very popular with Tradespeople and Fabricators because of their range and versatility. Adaptable and reliable, they are an essential instrument, always in stock in every tradie’s toolbox.

These are fantastic for DIY door latches, simply recess the countersunk magnet into your door frame and attach a metal strip or strike plate to the door. Countersunk magnets are useful for a whole range applications, remediating an assortment of issues around the garage, home or worksite.

Rare Earth Neodymium magnets are the strongest permanent magnets commercially available and are the ideal magnet if you require maximum magnetic strength. They are many times stronger than traditional magnets and come in a huge range of sizes, shapes and grades. Rare Earth magnets are magnetically stable and have a strong resistance to demagnetization however they are not suitable for use in high temperature applications.

Due to their greater strength to size ratio, Neodymium magnets have now replaced Alnicos and Ferrites in many engineering and mechanical industries. Being smaller and lighter than traditional magnets they are ideal for applications such as, bearings, speakers and headphones, hard disks, wind turbines and electric cars to name just a few.

Typical Physical Properties

NB: Ranges are indicative for product category, please check individual products for specic values within that range.

Production Flow Diagram

Demagnetization Curves

Surface Treatment

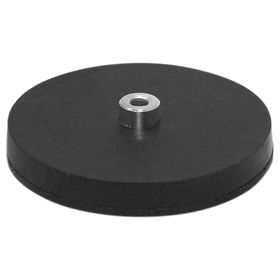

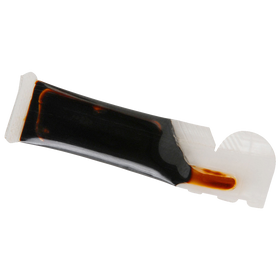

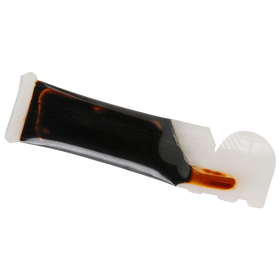

The most common coating for Neodymium magnets is Nickel + Copper + Nickel (Ni + Cu + Ni). This coating offers the magnet relatively good protection from corrosion and passive applications. If the magnet will be exposed to moisture or liquid then consider the use of an organic coating such as Epoxy. A hard wearing coating, Epoxy is suited to applications where the magnet will come under some friction or knocking.

Range and Tolerance

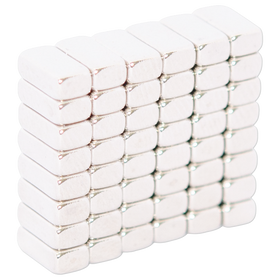

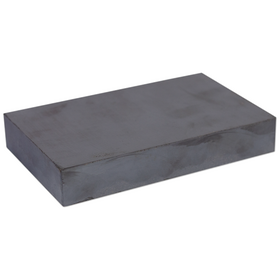

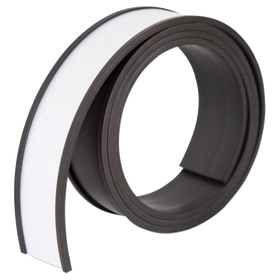

Magnets are readily available in Blocks, Discs, Cylinders & Rings. AMF Magnetics specializes in the supply of short-run prototype magnets including Arc Segments, various magnetic orientations etc. If you need a magnet size that we don't carry in stock, submit a Design-a-Magnet enquiry for a quote on your custom magnet design.

Magnetic Properties

Neodymium magnets are offered in several different grades. The first section N30-54 has an operating temperature of up to 80 degrees. Most of our stock only goes up to N38. The second section, denoted with the "M" prefix after the grade has an operating temperature 100 degrees. After this the grades are "H", "SH", "UH" & "EH". In order for the magnet to withstand a higher operating temperature, during production more of the raw material PrNd is incorporated as these elements have a naturally occurring resistance to high temperatures.

Returns Policy

If you are not entirely satisfied with your purchase, we're here to help.

We have a 30 Day Returns policy at Frenergy Magnets. You may return your item within 30 days of receiving it to receive a refund.

The product/s must be unused and in the same condition you received them in. Please contact us at info@frenergy.com.au to initiate the returns process.

The buyer is responsible for the cost of returning the order.