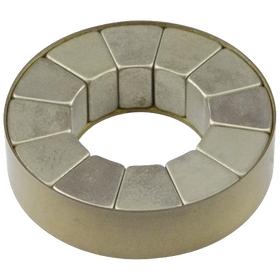

Neodymium Fishing Eyelet Hook Magnet 60mm | Pull 113kg

Same Day Dispatch

Order before 1pm to qualify for same day dispatch.

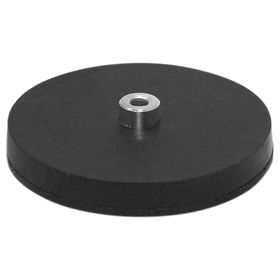

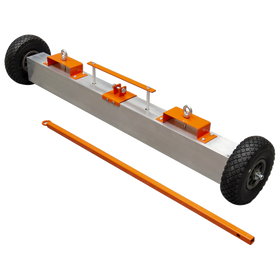

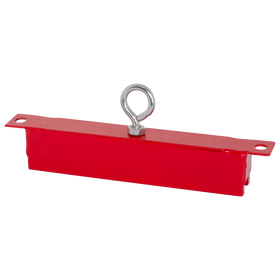

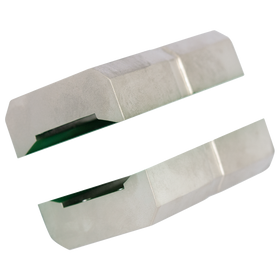

Shipwrights, Military engineers and Mining operations of all kinds find these large Pot Magnets a valuable tool for keeping their businesses efficient and profitable. The attached eyelet transforms the magnet into a highly functional tool that can help prevent accidents and improve safety levels in the workplace. Pot magnets are designed for both strength and durability at a level not found in standard Neodymium products. This is largely due to the protective nature of the steel cap that shields the fragile magnet from bumps and knocks, while also having a magnifying effect on the magnetic field which is emitted predominantly from the uncapped base of the magnet. Reliable, predictable and permanent performance are the qualities that make this type of magnet preferable in industrial and commercial settings. The ability of permanent magnets to operate in remote, unpowered locations or “off the grid” is also highly valued by people like mine managers or engineers in the armed forces. Keeping hoses, ropes, cables, and other equipment in the correct position and in an organised fashion is often crucial to the effectiveness or success of many large-scale operations.

In recent times large Pot magnets with eyelet attachments have been fitted with ropes and used by underwater fossickers to retrieve metal valuables or lost equipment from rivers, ponds or the seabed. The use of these Eyelet magnets as a retrieval tool has proved to be very effective.

Typical Physical Properties

NB: Ranges are indicative for product category, please check individual products for specic values within that range.

Production Flow Diagram

Demagnetization Curves

Surface Treatment

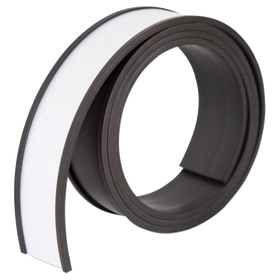

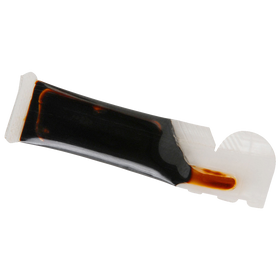

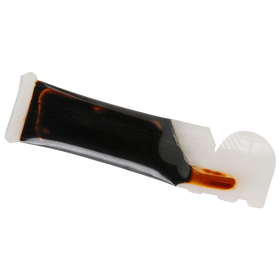

The most common coating for Neodymium magnets is Nickel + Copper + Nickel (Ni + Cu + Ni). This coating offers the magnet relatively good protection from corrosion and passive applications. If the magnet will be exposed to moisture or liquid then consider the use of an organic coating such as Epoxy. A hard wearing coating, Epoxy is suited to applications where the magnet will come under some friction or knocking.

Range and Tolerance

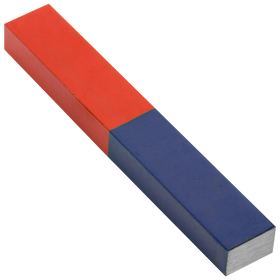

Magnets are readily available in Blocks, Discs, Cylinders & Rings. AMF Magnetics specializes in the supply of short-run prototype magnets including Arc Segments, various magnetic orientations etc. If you need a magnet size that we don't carry in stock, submit a Design-a-Magnet enquiry for a quote on your custom magnet design.

Magnetic Properties

Neodymium magnets are offered in several different grades. The first section N30-54 has an operating temperature of up to 80 degrees. Most of our stock only goes up to N38. The second section, denoted with the "M" prefix after the grade has an operating temperature 100 degrees. After this the grades are "H", "SH", "UH" & "EH". In order for the magnet to withstand a higher operating temperature, during production more of the raw material PrNd is incorporated as these elements have a naturally occurring resistance to high temperatures.

Returns Policy

If you are not entirely satisfied with your purchase, we're here to help.

We have a 30 Day Returns policy at Frenergy Magnets. You may return your item within 30 days of receiving it to receive a refund.

The product/s must be unused and in the same condition you received them in. Please contact us at info@frenergy.com.au to initiate the returns process.

The buyer is responsible for the cost of returning the order.