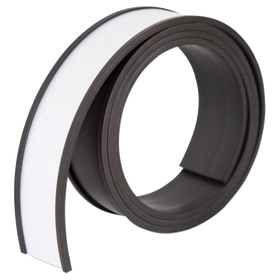

Neodymium NeoFlex® Magnetic Strip - 12.5mm x 1.5mm x 1M | Self-Adhesive 3M VHB 4910

Same Day Dispatch

Order before 1pm to qualify for same day dispatch.

Magnetic Product Description:

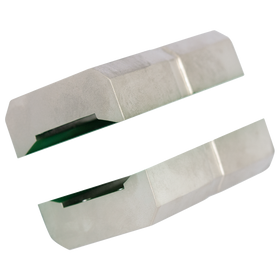

- Made from Neodymium powder within a polymer matrix, this Magnet Strip is the strongest of our flexible magnetic tapes.

- This Rare Earth Magnetic Strip has a width of 12.5mm, a thickness of 1.5mm and a length of 1metre.

- This product is ideal for use where Ferrite tapes lack enough magnetic strength.

- Typical uses are for securing and displaying banners, signage and heavy items (It has a pull force of 450 g/cm²).

- Versatile and super-strong 3M VHB 4910 adhesive backing to the powerful Neodymium tape

Click Here for instruction for installation

Please note: We don’t recommend this product for outdoor use, where it can be exposed to moisture, damp or wet surfaces and/or weather, if slight rusting is of concern.

Uses for our Rare Earth NeoFlex® Magnetic Tape:

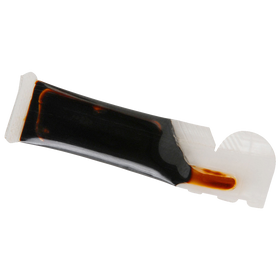

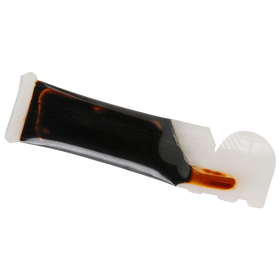

As the name suggests, this NeoFlex® 1 metre length of adhesive-backed magnetic tape contains super-strong Neodymium magnetic material within a rubberised medium that gives it excellent flexibility. The addition of versatile and super-strong 3M VHB 4910 adhesive backing to the powerful Neodymium tape results in the ultimate magnetic product that can bond strongly and instantly to a huge range of surfaces including sleek, lightweight modern materials that would otherwise lose structural integrity if attached using traditional penetrative fasteners.

The VHB 4910 adhesive backing takes an already state-of-the-art NeoFlex® magnetic tape product to a new level. Industrial-grade levels of adhesion are obtained with VHB 4910 adhesive and this allows architects and engineers to reconsider design and construction methods where power tools and mechanical fasteners have previously been typical requirements.

3M VHB 4910 adheres instantly without the usual curing period associated with common glues and bonds strongly with a multitude of materials including sealed timber, sealed concrete, glass, metals, PVC, acrylic, polycarbonate and most painted surfaces. VHB 4910 adheres permanently and is highly heat resistant which makes it an excellent alternative to welds, rivets and screws.The reduction in assembly time and employee skill levels makes the innovative VHB 4910 backed NeoFlex® magnetic tape a serious alternative contender for modern construction techniques and product designs that want to avoid using unsightly conventional fasteners and the usual construction and maintenance costs.

Typical Physical Properties

NB: Ranges are indicative for product category, please check individual products for specic values within that range.

Production Flow Diagram

Demagnetization Curves

Surface Treatment

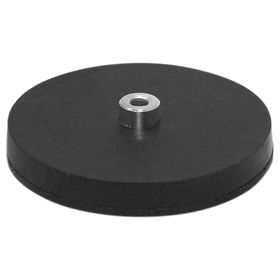

The most common coating for Neodymium magnets is Nickel + Copper + Nickel (Ni + Cu + Ni). This coating offers the magnet relatively good protection from corrosion and passive applications. If the magnet will be exposed to moisture or liquid then consider the use of an organic coating such as Epoxy. A hard wearing coating, Epoxy is suited to applications where the magnet will come under some friction or knocking.

Range and Tolerance

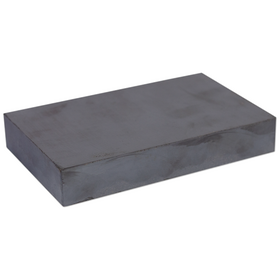

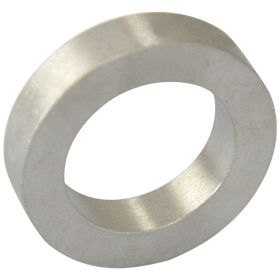

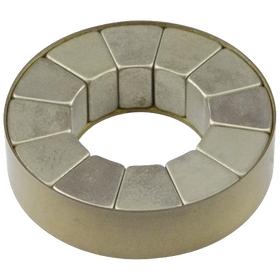

Magnets are readily available in Blocks, Discs, Cylinders & Rings. AMF Magnetics specializes in the supply of short-run prototype magnets including Arc Segments, various magnetic orientations etc. If you need a magnet size that we don't carry in stock, submit a Design-a-Magnet enquiry for a quote on your custom magnet design.

Magnetic Properties

Neodymium magnets are offered in several different grades. The first section N30-54 has an operating temperature of up to 80 degrees. Most of our stock only goes up to N38. The second section, denoted with the "M" prefix after the grade has an operating temperature 100 degrees. After this the grades are "H", "SH", "UH" & "EH". In order for the magnet to withstand a higher operating temperature, during production more of the raw material PrNd is incorporated as these elements have a naturally occurring resistance to high temperatures.

Returns Policy

If you are not entirely satisfied with your purchase, we're here to help.

We have a 30 Day Returns policy at Frenergy Magnets. You may return your item within 30 days of receiving it to receive a refund.

The product/s must be unused and in the same condition you received them in. Please contact us at info@frenergy.com.au to initiate the returns process.

The buyer is responsible for the cost of returning the order.