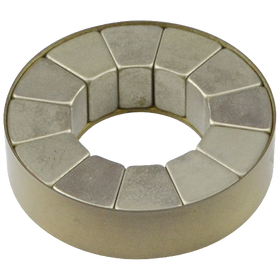

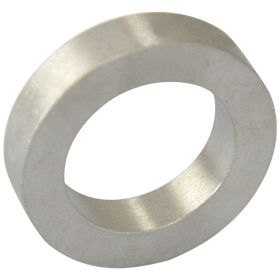

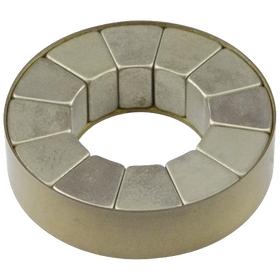

Neodymium Ring Magnet OD15mm x H3mm | Hole 9mm N35

Same Day Dispatch

Order before 1pm to qualify for same day dispatch.

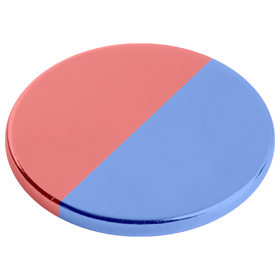

Neodymium Ring Magnets

Strong Neodymium Ring magnets placed on each side of an opening with the opposing North and South poles facing each other is one of many methods of creating a magnetic closure system for such things as fashion items, storage bins, cabinets and any other situation where mechanical closure methods are visually unsuitable or otherwise inappropriate. Unlike solid Block or Disc shaped permanent magnets, Ring magnets are easily held in position with some form of round lug, shaft or pin that has the corresponding diameter to the central hole (ID) of the Ring magnet. In other circumstances, two Ring magnets with opposing poles may be attached to each side of an opening with wire, string, cord or a similar material. This method is fast, simple and especially convenient for occasional use or isolated outdoor holding applications. Single ring magnets can also be used to bond with ferrous surfaces around the workplace or, as another option, a metal washer can be easily attached to non-ferromagnetic surfaces such as timber fencing or sheds, to create a ferrous attachment point for the magnet. Farmers, maintenance workers and many tradespeople find this type of magnetic attachment extremely practical and also offers considerable time saving benefits when performing their daily work schedule.

Typical Physical Properties

NB: Ranges are indicative for product category, please check individual products for specic values within that range.

Production Flow Diagram

Demagnetization Curves

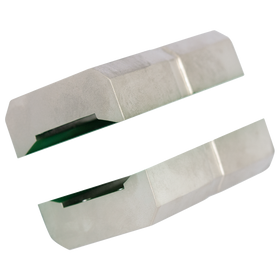

Surface Treatment

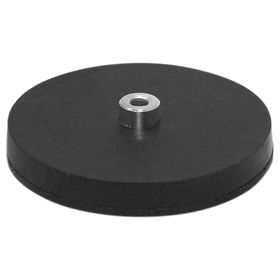

The most common coating for Neodymium magnets is Nickel + Copper + Nickel (Ni + Cu + Ni). This coating offers the magnet relatively good protection from corrosion and passive applications. If the magnet will be exposed to moisture or liquid then consider the use of an organic coating such as Epoxy. A hard wearing coating, Epoxy is suited to applications where the magnet will come under some friction or knocking.

Range and Tolerance

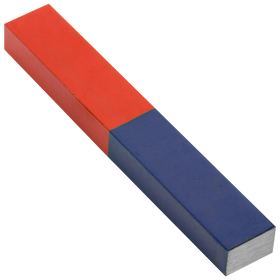

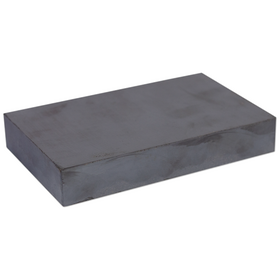

Magnets are readily available in Blocks, Discs, Cylinders & Rings. AMF Magnetics specializes in the supply of short-run prototype magnets including Arc Segments, various magnetic orientations etc. If you need a magnet size that we don't carry in stock, submit a Design-a-Magnet enquiry for a quote on your custom magnet design.

Magnetic Properties

Neodymium magnets are offered in several different grades. The first section N30-54 has an operating temperature of up to 80 degrees. Most of our stock only goes up to N38. The second section, denoted with the "M" prefix after the grade has an operating temperature 100 degrees. After this the grades are "H", "SH", "UH" & "EH". In order for the magnet to withstand a higher operating temperature, during production more of the raw material PrNd is incorporated as these elements have a naturally occurring resistance to high temperatures.

Returns Policy

If you are not entirely satisfied with your purchase, we're here to help.

We have a 30 Day Returns policy at Frenergy Magnets. You may return your item within 30 days of receiving it to receive a refund.

The product/s must be unused and in the same condition you received them in. Please contact us at info@frenergy.com.au to initiate the returns process.

The buyer is responsible for the cost of returning the order.