Portable Magnetic Plate Lifter - 30kg Capacity | Magnetic Lifting Device

Same Day Dispatch

Order before 1pm to qualify for same day dispatch.

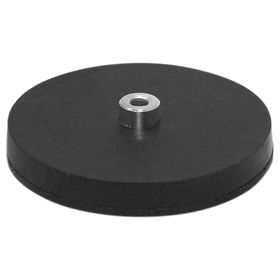

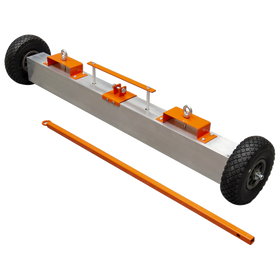

- If your business involves working with metal sheet such as a metal fabrication workshop, foundry, scrap yard or recycling plant, magnetic Plate Lifting tools like this 30KG model are ideal.

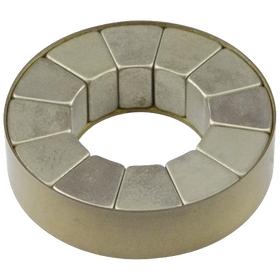

- These lifters are lightweight, hand-operated and the enclosed permanent magnets do not require electrical power to operate which makes them totally portable.

- The devices are designed to lift and maneuver thin sheets of steel and other ferrous material and can help to improve workplace efficiency and safety by allowing the metal sheet to be transported, relocated and stored in a faster, safer, hands-free way.

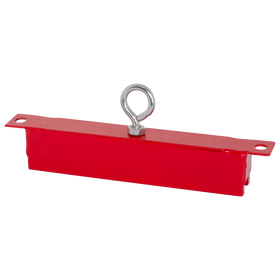

- The tool attaches to metal sheets magnetically and releases the sheet when the lever is lowered to the horizontal position.

- Workplace injuries of a minor or more serious kind are greatly reduced in industries such as steel manufacturing and metalworking when these magnetic lifters are introduced and used on a daily basis.

- Stacking and unstacking sheets of corrugated iron or metal cladding around a construction site can become easier and safer task to perform when using these practical magnetic plate lifters.

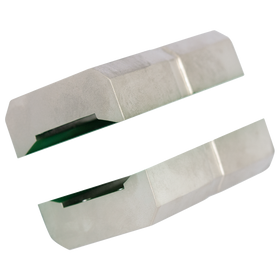

LOCK. The handle has three positions. Two handle positions lock or engage the load. The third position, indicated by the off sign, releases the load. The two lock positions, perpendicular and horizontal, lock onto the steel goods to drag, lift or carry.

LOAD. With the handle extended down in one of the two lock and load positions, sheets of steel can carried vertically, between the arm and the hip, in order to move through a narrow corridor. Alternatively, steel goods can be locked and the weight loaded through these magnetic lifters with the handle in the upright or perpendicular position and materials carried on the flat.

Returns Policy

If you are not entirely satisfied with your purchase, we're here to help.

We have a 30 Day Returns policy at Frenergy Magnets. You may return your item within 30 days of receiving it to receive a refund.

The product/s must be unused and in the same condition you received them in. Please contact us at info@frenergy.com.au to initiate the returns process.

The buyer is responsible for the cost of returning the order.