A Complete Guide to Rare Earth Magnets

What is a rare earth magnet?

A rare earth magnet is a type of permanent magnet made from alloys of rare earth elements, known for their exceptional magnetic strength. These magnets are the strongest available commercially, much more powerful than other types of permanent magnets like ferrite or alnico magnets. There are 17 rare earth minerals in the Lanthanide series of metals in the periodic table. The two most common rare earth magnets are neodymium (Nd-Fe-B) and samarium cobalt (SmCo).

Despite the name, rare earth elements are actually abundant in the Earth's crust but are called 'rare' because they are not frequently found in concentrated deposits and are mixed in with other elements. The process of extracting rare earths is economically challenging due to low concentration of rare earth ore deposits among those other elements, and the high-tech requirements to obtain pure rare earth materials from that process. As a result, only a few sources provide most of the world’s supply of rare earth elements.

China is the world's largest producer of rare earth metals, with reserves estimated at 44 million metric tons. After China, the United States, Vietnam, Russia, and Brazil are the next largest producers of rare earths.

What is the difference between a rare earth magnet and a regular magnet?

Rare earth magnets have several key properties, including high magnetic strength, compact size, brittleness and temperature sensitivity. Their strong magnetic fields allow for more efficient and compact designs in various technologies. Rare earth magnets are used in a wide range of applications due to their superior magnetic properties.

Neodymium magnets are comprised of an alloy of neodymium, iron, and boron, and they are the strongest type of permanent magnet. They are widely used in applications requiring powerful magnetic strength, such as electric motors, hard disk drives, medical devices and consumer electronics. Neodymium magnets are also more compact than regular magnets because of their magnetic power to weight ratio and are highly sought after for use in electronic devices such as smartphones, communication devices, sensors, jewellery and other applications where components need to be extremely small.

Neodymium magnets are brittle and can chip or break if not handled carefully and can lose their magnetic properties at high temperatures. Samarium-cobalt magnets are made from an alloy of samarium and cobalt and offer excellent temperature stability and resistance to demagnetisation and corrosion, making them suitable for high-temperature environments and applications in aerospace, and medical industries.

Because samarium-cobalt magnets can withstand higher temperatures, they perform in challenging environments without significant loss of magnetism. They are essential in electronics, motors and generators, medical devices, renewable energy systems, and consumer products. The advantages of rare earth magnets include their exceptional strength and versatility, making them crucial in modern technology. However, challenges such as high production costs, supply chain vulnerabilities, and environmental impacts associated with mining and processing rare earth elements need to be managed to ensure their sustainable use.

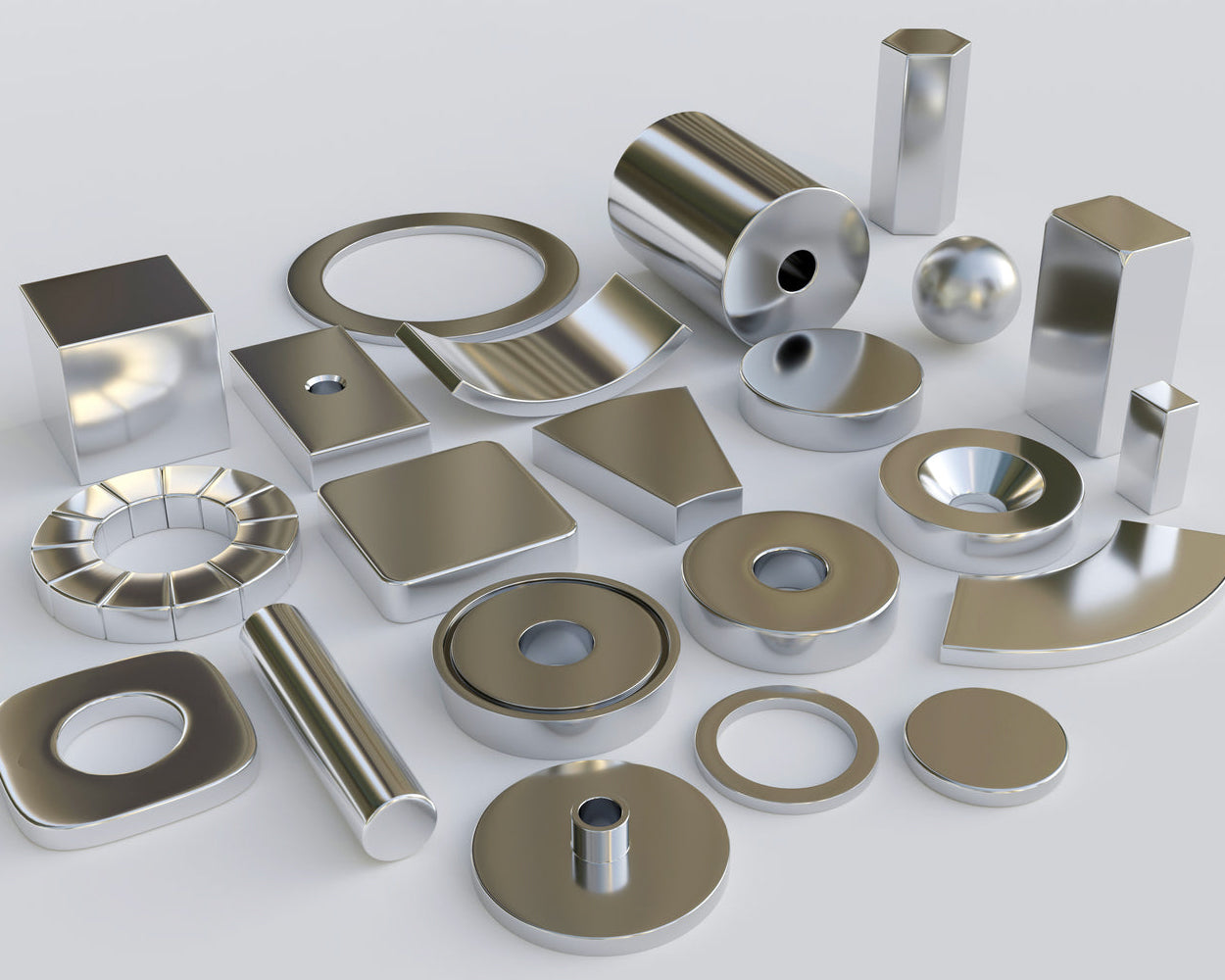

What are the types of rare earth magnets?

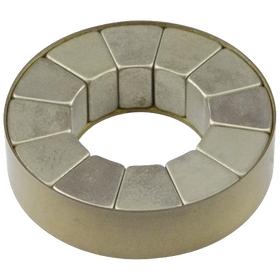

The two main types of rare earth magnets are neodymium magnets and samarium-cobalt magnets. Neodymium magnets, also known as NdFeB magnets, are made from an alloy of neodymium, iron, and boron. They are renowned for their extremely high magnetic strength, making them the strongest type of permanent magnet available commercially. These magnets are widely used in applications requiring high magnetic strength, such as electric motors, hard disk drives, medical devices, magnetic resonance imaging (MRI), consumer electronics, and renewable energy technologies like wind turbines. Neodymium magnets exhibit a high ability to retain magnetisation, but are brittle and prone to corrosion, which is why often neodymium magnets often have protective coatings like nickel or epoxy. Neodymium magnets are also sensitive to high temperatures, which can reduce their magnetic properties.

Samarium-cobalt magnets, or SmCo magnets, are made from an alloy of samarium and cobalt. Although they are not as strong as neodymium magnets, samarium-cobalt magnets still offer significant magnetic strength. They are typically used in high-temperature environments and applications requiring corrosion resistance, such as aerospace, military, medical devices and high-performance motors. Samarium-cobalt magnets are characterised by excellent temperature stability and can operate at much higher temperatures than neodymium magnets without losing their magnetic properties. Additionally, samarium-cobalt magnets are resistant to oxidation and corrosion and maintain their magnetic strength over a wide range of temperatures. However, samarium-cobalt magnets are more brittle and generally more expensive than neodymium magnets. Both types of rare earth magnets provide substantial advantages in terms of magnetic strength and performance, making them critical components in many modern technologies and industrial applications.

What makes rare earth magnets so strong?

Rare earth magnets are so strong because they are made from alloys containing rare earth elements, which possess unique atomic structures that contribute to their exceptional magnetic properties. The two primary rare earth elements used in these magnets are neodymium and samarium. These elements have large magnetic moments due to their unpaired electrons in the f-orbital, which generate strong magnetic fields.

In neodymium magnets, the combination of neodymium, iron, and boron results in a crystal structure that aligns the magnetic domains more effectively, leading to a higher overall magnetic strength. The dense arrangement of atoms in these rare earth magnets allows for a greater number of magnetic moments to align in the same direction, significantly boosting their magnetic field strength.

Samarium-cobalt magnets also exhibit high magnetic strength due to the combination of samarium and cobalt, which creates a highly stable and strong magnetic structure. The strong exchange interactions between the samarium and cobalt atoms contribute to their robust magnetic properties, even at elevated temperatures.

Additionally, rare earth magnets have high coercivity, meaning they can withstand demagnetising forces without losing their magnetism. This property ensures that the magnets maintain their strong magnetic fields even under challenging conditions. The unique electron configurations and strong interatomic interactions in rare earth elements are the primary reasons behind the exceptional strength of rare earth magnets.