What Are Magnet Lifters - And How Do They Work?

What Are Magnetic Lifters?

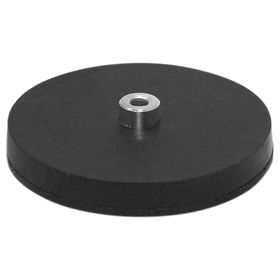

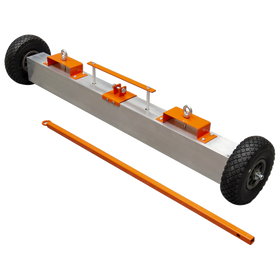

A magnetic lifter is a device that uses a powerful magnet to lift and move ferromagnetic materials such as steel and iron. Magnetic lifters operate without the need for electricity, relying on a strong permanent magnet to generate a magnetic field. The lifter is equipped with a handle or lever that activates or deactivates the magnetic force, which gives it a secure attachment to and release from the load. Magnetic lifters are commonly used in industrial settings for handling heavy metal parts, sheets and scrap, providing a safe and efficient means of material handling and transportation.

In manufacturing, magnetic lifters handle metal sheets, parts and assemblies. In warehouses, they facilitate the movement of heavy steel products. In shipbuilding, magnetic lifters move large metal components. In construction, they move steel beams and other ferromagnetic materials. In recycling plants, magnetic lifters are essential for handling scrap metal efficiently. In automotive industries, magnetic lifters assist in moving car parts and assemblies. In steel mills, they are used for handling raw materials and finished products. In metal fabrication shops, magnetic lifters move metal plates and profiles easily. It is easy to see why the versatility and reliability of magnetic lifters makes them such an essential device for a wide range of industries.

Magnetic lifters also improve safety by reducing the need for manual handling of heavy metal objects. They increase efficiency in lifting and moving ferromagnetic materials, saving time and labour. Magnetic lifters do not require electricity, making them cost-effective and reliable even in power outages. They offer strong and secure holding power, minimising the risk of accidentally dropping materials. Magnetic lifters are easy to operate, and they work using a simple handle or lever mechanism. They also reduce the potential for damage to materials because they don't rely on clamps or hooks that can scratch or dent surfaces.

Are Magnetic Lifters Safe?

Magnetic lifters are very safe when they're used properly. They improve workplace safety by reducing manual lifting of heavy objects, thereby lowering the risk of injuries. Magnetic lifters have strong holding power, which allows them to securely lift and move materials, minimising the risk of dropping. Safety always depends on correct usage however, and operators should make sure the load capacity is not exceeded, that they are aware of the pull force of the magnetic lifter they are operating and that the lifting surfaces are clean and flat for maximum magnetic contact. Regular inspection and maintenance of the lifter are crucial to ensure its reliability and safety. Operators who use magnetic lifters need proper training so they can work with these powerful devices safely and professionally. In the right environment, magnetic lifters are a powerful device that can add efficiency and safety to a wide range of industrial workplaces.

How Long Have Magnetic Lifters Been Used In Industry?

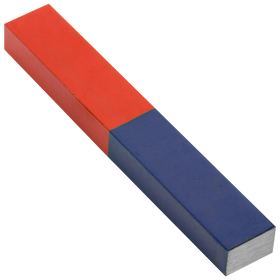

Magnetic lifters, in the form of simple magnetic lifting devices, were first used in industrial applications in the early to mid-20th century. As technology advanced, particularly in the development of strong permanent magnets like Alnico and later rare earth magnets such as neodymium, more effective and powerful magnetic lifters were designed. These improvements significantly improved the lifting capacity and safety of magnetic lifters, making them more practical. As a result, magnetic lifters were widely adopted in various industries. Specific records detailing the exact date of the first use are sparse, but by the 1950s and 60s, many industries had adopted this new m agnetic technology.

What Are The Safety Precautions For Dynamic Lifters?

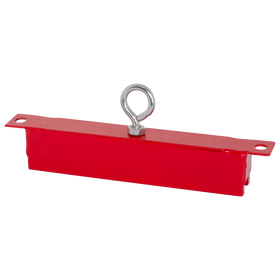

Safety precautions are a priority factor when operating a magnetic lifter. There are several important practices to ensure safe and efficient operation of a magnetic lifter. Operators should receive proper training and follow the manufacturer's guidelines. The load capacity should never be exceeded, and the magnetic lifter should be used only on materials within its specified weight range. Regular inspection and maintenance of the magnetic lifter are crucial to detect and address any wear or damage.

Before use, the operator should make sure the lifting surfaces are clean and free of debris to achieve maximum magnetic contact. It is important to that the magnetic lifter is securely attached to the load before lifting, and to avoid sudden movements or impacts that could dislodge the load. There are also some commonsense principles, such as keeping hands and other body parts away from the lifting area to prevent injuries. When it's not in use, the magnetic lifter should be stored in a safe and secure place to prevent accidental engagement.

As well as following the operating guidelines, anyone using a magnetic lifter should also make sure they are wearing appropriate personal protective equipment, such as gloves and safety shoes, and follow any specific safety protocols established for the work environment. Proper use of locking mechanisms and adherence to safety features integrated into the magnetic lifter also contribute to its safe operation.

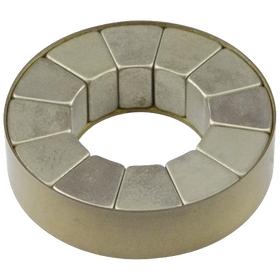

What Are The Size Of The Magnets Used In Magnetic Lifters?

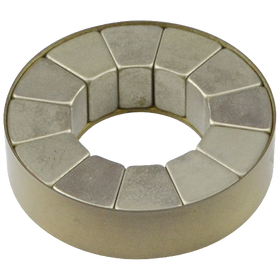

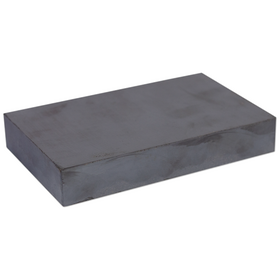

The size of the magnets used in dynamic lifters can vary widely depending on the specific application and the lifting capacity required. Magnetic lifters are equipped with powerful permanent magnets, often made from materials like neodymium or ferrite, which can be configured into various shapes and sizes to meet different needs.

For small to medium-sized lifting applications, magnets may range from a few centimetres in diameter and thickness to larger dimensions. For heavy-duty industrial lifters, the magnets can be much larger, sometimes measuring several tens of centimetres in length, width and thickness.

The actual size of the magnet is determined by factors such as the weight of the materials to be lifted, the type of materials, the required holding force, and the design of the lifter. Manufacturers typically design these magnets to balance lifting strength with practical handling and safety considerations.