Choosing The Right Magnet

Do Your Research

Choosing the right magnet for your application requires some research, because all magnets are not created equal. A magnet that may be perfect for your whiteboard may not be what you need for a heavy-duty job in the warehouse. So, buckle up for a tour of the magnet world.

Let's start with the most important factors to consider before deciding on the magnet you should use. For optimal performance and efficiency, you'll need to know what type of magnet is required, its strength, size and material composition.

What Strength Magnet Do I Need?

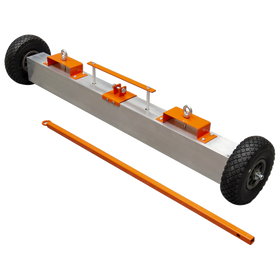

Different applications demand varying levels of magnetic strength. For instance, industrial applications may require strong, durable magnets made from rare earth magnetic material while consumer products – toys, fridge magnets and less demanding applications - may need smaller, less powerful magnets. You can find out just how strong your magnet is by looking at the specifications. You'll see a rating called 'Gauss' which is a measurement of magnetic strength. The higher the rating, the stronger the magnet. At Frenergy, we have a team of experts on hand and if you are uncertain about the strength and the Gauss requirement, just ask.

How Do I Know What Type of Magnet Is Right for Me?

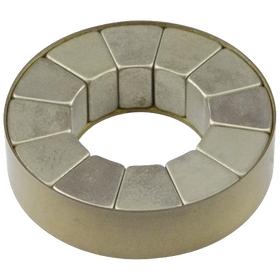

The next step in the process of selecting the right magnet for the job is to consider the type of magnet that suits your needs. Magnets are made from a range of elements, from what is known as ''rare earth', to iron oxides and a combination of other minerals. So, let's look at the material composition of magnets, because that will help you make the right choice for your application. Let's start with the rare earth magnets. There are two magnet types made from rare earth elements – neodymium and samarium cobalt. Neodymium magnets are made from an alloy of neodymium, iron, and boron, and are among the strongest available. Samarium cobalt magnets consist of samarium and cobalt, offering excellent temperature stability. Alnico magnets are made from aluminium, nickel, and cobalt. Alnico magnets also often contain traces of other metals that can enhance specific characteristics. Alnico magnets have been in use for about 100 years. They were some of the first permanent magnets to be developed, and because of their relative strength and stability, they are still widely used today.

Alnico magnets are not as strong as samarium cobalt or neodymium magnets. Despite that, they offer exceptional magnetic stability even at extremely high operating temperatures, higher than any other type of permanent magnet, but Alnico magnets are relatively susceptible to demagnetisation.

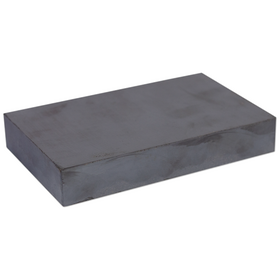

Ferrite magnets are composed of iron oxide and ceramic materials, providing a good balance between cost and performance. Some ferrite magnets have pure iron, and others consist of iron mixed with barium and iron oxide or strontium carbonate.

Ferrite magnets are much weaker than neodymium or samarium cobalt magnets but they are much more economical to produce and their low production costs often offset this disadvantage. Worldwide, ferrite magnets are the most commonly used magnets in applications where exceptionally high magnetic performance is not a necessity.

In summary, permanent magnets, such as neodymium, samarium cobalt and ferrite, are commonly used due to their ability to retain magnetism over long periods. Neodymium magnets are known for their exceptional strength and are ideal for compact applications where powerful magnetic fields are necessary. Samarium cobalt magnets, while slightly less powerful, offer better temperature stability and corrosion resistance, making them suitable for high-temperature environments. Ferrite magnets, although weaker, are cost-effective and work well in low-intensity applications.

Size Matters

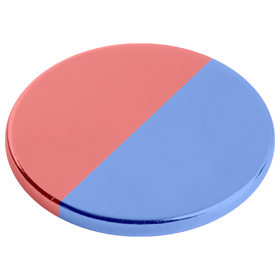

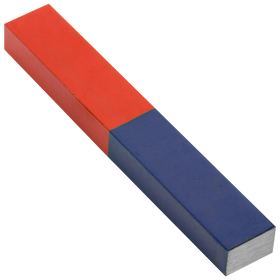

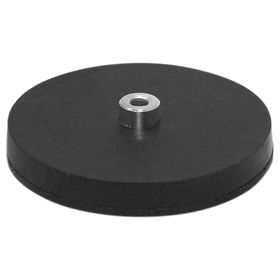

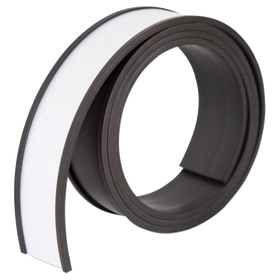

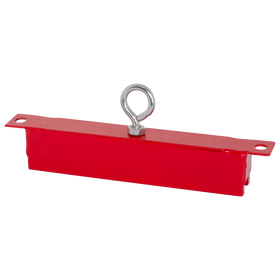

The size and shape of the magnet also play a significant role. The physical dimensions must align with the space constraints of your application. Smaller magnets are often used in electronics and medical devices, while larger magnets are found in industrial machinery and automotive components. The shape affects the distribution and focus of the magnetic field. Magnets come in many different shapes, including bars, rings, discs, horseshoes, cubes, spheres, strips and rectangles, and the shape of the magnet you choose will have a direct impact on its usefulness.

The shape of the magnet you require will be dependent on your application, so that is an important consideration before making your decision. For example, a disc magnet may be used for more mechanical projects whereas a horseshoe magnet is more commonly used for holding objects.

Temperature Matters Too!

Temperature tolerance is an important consideration. Different magnets have varying levels of resistance to temperature changes. Neodymium magnets, while strong, can lose their magnetic properties at high temperatures. Samarium cobalt magnets, on the other hand, maintain their magnetism in extreme heat, making them suitable for high-temperature applications. Alnico magnets have the highest maximum operating temperature of all the permanent magnet family, not suffering irreversible losses in performance until the temperature reaches an astounding 525°C.

Unique among permanent magnets, ferrite magnets actually become more resistant to demagnetisation as their temperature increases but their strength slowly decreases as their temperature rises.

Environmental conditions, such as exposure to moisture or chemicals, should also be taken into account. Some magnets, like neodymium, are prone to corrosion and may require protective coatings. Samarium cobalt and ferrite magnets offer better resistance to corrosion, making them suitable for harsh environments.

Another factor to consider is the cost and availability of the magnet. Neodymium magnets are generally more expensive due to their strength and manufacturing complexity. Ferrite magnets are more affordable and widely available, making them a popular choice for many applications.

Ask Us – We Know Magnets!

Finally, consult with our magnet specialists at Frenergy. We live and breathe magnets every day and we're here to help you make the right choice for your application. We will provide valuable insights and recommend the most suitable magnet based on your specific requirements. Understanding the technical specifications and performance characteristics of different magnets will ensure that you select the right one to get the job done efficiently and effectively. For all the information you need to make the right magnet choice, visit frenergy.com.au. We have Australia's largest range of magnets and the best team of experts who will help take your project from the drawing board to successful completion.