Technical Magnet Questions

Is there a North and South Pole or one pole?

Every type of magnet has at least one North and South pole pairing. Some rare, specially designed or purpose magnets can have more than one pair of North and South poles and are known as multi-pole magnets. Without the flow of magnetic energy between the North and South poles, the attracting and repelling forces of magnetism would not be possible.

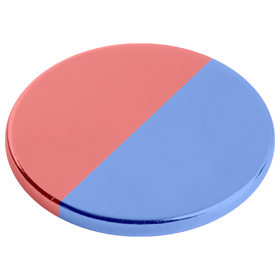

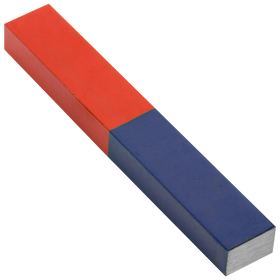

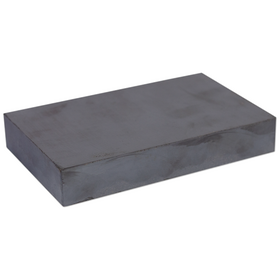

Axial Orientation: Nearly all the Neodymium magnets that Frenergy stocks are axially magnetised. This magnetic orientation is applied during manufacturing. and as a result, these rare earth products have a North and South pole on the opposite surfaces of the magnet. This axial type of orientation means the North to South magnetic flow is travelling through the thickness (height) dimension. In the case of disc-shaped magnets, the two poles will be apparent on the opposing flat, round surfaces. For block magnets, the two poles are found on flat rectangular or square surfaces. Cylinder magnets will also have two poles at the flat surface at each end of the magnet.

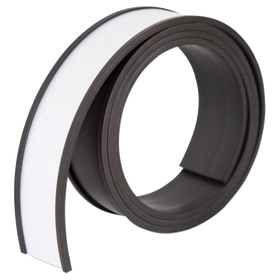

Single Side Orientation: Some thin, weaker or flexible magnetic materials can be manufactured with both poles on one surface of the magnet. Some non-flexible hard Ferrite Magnets can also be manufactured with both poles on one side. In these cases, the North and South poles are applied to the magnet in a striped or alternating North and South pole pattern. Products like magnetic tapes, labels and fridge magnets are the best example of this type of magnetic field orientation. Both North and South poles alternate across the back of the magnet so the back of the magnet will bond to the fridge or any other metal surface. The outward face is not magnetic at all. This type of magnetisation is sometimes referred to as single-sided magnetic orientation. It can improve the holding ability of small Ferrite magnets or Flexible Magnets and helps to reduce the gravitational effect of shear forces when a magnet is attached vertically to steel. Some of these flexible magnets have a convenient self-adhesive backing for attaching graphics, signage or advertising.

What is the life cycle of the magnetism in a magnet?

All magnets with the exception of Electromagnets are called Permanent Magnets. The magnetic field of Permanent Magnets which are made from mined mineral resources does not degrade with the passing of time under normal conditions. However, outside influence can certainly impact the magnetic properties of Permanent Magnets and can cause their magnetic power to diminish or, in severe circumstances, even disappear completely. Any outside influence that impacts the alignment of the magnetic material inside the magnet can damage the efficiency and power of its magnetic field. Temperatures over 80℃ will start to impact the alignment of magnetic material inside most Neodymium magnets. The magnet can recover if the exposure time is short but extended exposure can damage the magnetic alignment of the magnet permanently. Mechanical damage, corrosion, contact with larger magnets and anything that disrupts the magnetic alignment between the North and South poles will reduce magnetic performance.

How long does it take for the magnetism to lose its strength?

Neodymium magnets do not lose strength unless damaged or exposed to unfavourable conditions for long periods. Short periods of exposure to temperatures over 80℃ may cause a temporary loss of magnetic strength to Neodymium magnets but in many cases, the loss will be recovered. Most Neodymium magnetic products will remain effective for many years under normal conditions but the impact of continuous or repeated exposure to heat, collision, breakage or corrosive forces will slowly take its toll, reducing the effectiveness of the magnetic field.

In applications where temperatures may exceed 80℃, it may be necessary to consider using special high temperature rated Neodymium magnets. Also consider Ferrite based magnets which although having their own limitations in terms of their naturally low mechanical strength and reduced magnetic power. are able to withstand temperatures up to 250-300℃, Alnico magnets or Samarium Cobalt magnets should also be considered for either their corrosion or temperature resistant properties.

Which magnet is stronger - the N35 or the N50?

Frenergy specialises in supplying customers with an extensive range of super strong permanent Neodymium Magnets. We stock numerous types of these rare earth magnetic products including very small micro magnets as well as very large magnets. Neodymium magnets are the strongest magnets available and even some of our smallest magnets can hold many times their own weight!

In the past, the dimensions and mass of any magnet will be a good indicator of its magnetic strength ie. larger magnets contain more magnetic material and are therefore magnetically stronger. However, the introduction of Neodymium material during the 1980s has meant larger weights can now be supported by smaller magnets that emit far stronger magnetic power. These superior Neodymium products can be further enhanced with incrementally stronger grades of Neodymium of which N52 is the highest/ and N35 is the lowest. Higher grades mean more magnetic power can be achieved with the same size magnet. This can be important for applications where stronger magnetic influence is required but space restrictions prevent using a larger magnet. Vehicle and alarm system sensors often benefit from this reduced size and weight advantage while not having to sacrifice any magnetic power.

Do magnets pose a health risk?

Every order dispatched to Frenergy customers contains a Safety Warning brochure with important advice regarding magnet care and handling instructions. Please read this important information before handling your magnets. Our returns policy only applied to undamaged magnets.

All magnets have the potential to cause physical injury. Small magnets are an extremely dangerous choke hazard for children and can cause serious organ damage if swallowed.

Large magnets can cause bruising, blisters, tendon damage or more serious injuries when mishandled. Magnets can influence electric circuits and should always be avoided by individuals who have Pacemaker devices.

- Correct handling can prevent potentially serious injuries to the skin and even bone damage.

- It is extremely important to handle magnets correctly at all times. Read and follow the instructions provided.

- Never allow children to handle magnets or access magnets without adult supervision.

- Shards or splinters from magnets can also cause injury when magnets snap together or when they attract strongly across a table or bench.

- PPE should be used to handle strong magnets and avoid injuries.

- Store magnets safely and prevent children from accessing the magnets.

Frenergy can not replace damaged magnets that have been mishandled or used incorrectly. You can read the Frenergy Returns Policy here.

Does low temperature affect the strength of the magnets (say -40C)?

While high temperatures are well known to have a detrimental impact on Neodymium material, super cold temperatures can actually have the opposite effect.

Most of the Neodymium magnets in the Frenergy catalogue remain fully operational at temperatures up to 80℃. Above this temperature limit, the magnetic properties of the Neodymium material will begin to decline and the overall magnetic strength will be reduced permanently. The decline in power occurs when the heat agitates and disrupts the alignment of the ferromagnetic particles inside the magnetic material.

Once overheating has occurred, the disrupted and misaligned particles are no longer able to maintain the maximum flow of magnetic field that was previously possible. However, at very low temperatures eg. -40℃ the particle alignment is actually enhanced and the flow of the magnetic field between the poles reaches the optimal level which in turn produces more magnetic power.

Gauss readings for a Neodymium magnet in these super cold environments can be slightly stronger than the same magnet in more ambient temperatures. If your application requires a magnet that can tolerate temperatures above 80℃ you can use Neodymium magnets that are specially produced for this purpose. Magnets with an N Grade suffix M can tolerate 100℃. Suffix H can tolerate up to 120℃. Suffix SH for temps up to 150℃. UH suffix for up to 180℃ and EH for up to 200℃

Can these magnets be machined to size in a lathe without damaging the magnetic field?

Any ex-factory modification to our Neodymium magnets is not recommended and will void any obligation for Frenergy to replace a faulty magnet.

Most non-flexible magnets are mechanically quite brittle and do not easily tolerate vibration, abrasion or mishandling. Any damage to a magnet usually results in either a partial or complete loss of magnetic power. Neodymium magnets are not designed to be machined or altered and the correct size magnet should be chosen in order to match your application precisely and without alteration. Modifying a Neodymium magnet by grinding or machining the surface will compromise the protective Nickel coating on the magnet and make it more vulnerable to damage.

Some Frenergy customers have lightly sanded the nickel coating with fine sandpaper to create a better bond when the magnet is attached to another surface with glue, however, we do not regard this as necessary and cannot recommend this treatment. Ferrite magnets can withstand a small amount of modification from grinding but in most cases, they will also incur a degree of increased structural fragility and reduced magnetic power.

With the flexible magnetic sheets, how strong can the magnet strength be?

With the flexible magnetic sheets, how strong can the magnet strength be? We are looking to hold items to the roof of a car at speed so the magnetic pull needs to be quite strong.

Magnetic sheets are thin and flexible. While this can offer advantages in many applications, it means the flexible sheet magnets are naturally magnetically weak and have little ability to support anything more than their own weight.

Most cars have body panels that are 2mm thick or less and do not provide an overly-strong attachment base for magnets of any kind. When attaching flexible sheet magnets to a car it is recommended that a 0.8mm thick sheet is used.

Thicker sheeting will always provide a better bond to the vehicle's body panel than thinner magnetic sheets. Attaching items other than wide, flat magnetic signage to a car will create a less aerodynamic shape. The item will be greatly impacted by wind and sheer forces as the vehicle travels along. Much will depend on the size and weight of what you want to magnetically attach to the car. The speed at which the car travels will also influence how well the magnet holds.

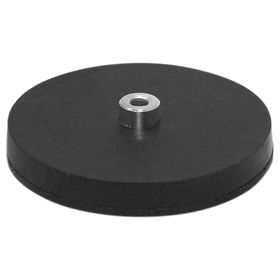

The more metal surface area that is in contact with the magnetic sheet, the stronger the bond will be. Frenergy has Rubber Coated Pot magnets that have extremely strong holding power but can bond to your car's bodywork without damaging the paint.

This category has magnets that bond strongly to your car body and there is a range of attachment options for mating the magnet to your non-magnetic item. These options include male thread attachment, female thread attachment, countersunk screw hole and even a cable tie attachment bracket. Choose the magnet that is strong enough to bear the weight of the item you want to attach and most suited to your requirements

I am interested in magnets that will repel each other in order to make one magnet float. Is this easy?

Arranging magnets to create the perfect environment where the repelling field between two magnets gives the appearance of one magnet “floating” or appearing to defy gravitational forces, is difficult.

The repelling force between like poles decreases as the distance between each magnet widens and at some point, the magnets will no longer interact. In order to suspend the magnet or make it hover, some guiding rails or some kind of physical restraint will be needed to hold the magnet in the precise position. With the repelling forces contained to some degree, the effects of gravity and the weight of the magnet you choose may allow the magnet to hover momentarily. In most cases, however, the repelling forces will push the magnet away from the field area and gravity will take over. The arrangement of multiple magnets that are positioned at equal intervals in a ring shape is often an easier way to produce a more even and equalised repelling field.

Creating levitational forces from the repelling nature of the same pole magnets is a highly technical challenge. Many physical factors and mathematical calculations need to be taken into account in order to successfully reproduce the phenomenon. In most magnetic levitation applications, at least one of the poles is created with an electromagnet. Controlling the power supply to the electromagnet makes the field strength adjustable and better suited to practical everyday applications eg. Japanese Maglev fast trains.

The mark on one side of the magnet represents which pole? Do you wear it with the mark on the skin or on the top side?

Some of the disc magnets in the Frenergy catalogue have a mark on one side. This mark can be a pen mark or a dimple applied to the magnet at the factory. The mark invariably indicates the North pole surface of the magnet. The South pole is therefore on the opposite side.

The flow of the magnetic field travels from the South pole area to the direction of the North pole. Some alternative health practitioners say the field can be applied to certain areas of the body to assist or improve blood flow which can help fast track the healing process. In their opinion, the North marked pole face should be applied directly onto the skin to have the most beneficial effect.

The North pole marker can be extremely useful when arranging two or more magnets so they either repel or attract each other. The mark can be used to identify each pole when the magnets need to be arranged correctly and then afterwards permanently fixed into place. Having the poles facing in the right direction can be crucial in many circumstances and applications.

Does using magnets on colorbond steel affect the magnet's stated holding power?

The thickness of the steel surface to which a magnet is attached has a big impact on the strength of the magnetic bond. Thicker steel surfaces will extract the maximum field density from the magnet. To fully achieve the pull forces stated in the Frenergy product description, the steel surface that the magnet bonds with should be at least 10mm thick and horizontally located.

Colorbond fencing is quite thin and mostly in a vertical plane, so a loss of around one-third of the magnet’s stated pull force on the website should be factored into holding expectations. It is very unlikely that even a large magnet could damage a Colorbond steel fence. For safety reasons, customers should choose a magnet with a pull-force capacity that is double the weight of the object they wish to suspend eg. PMYP-E20 should be loaded with a maximum of approximately 3kg on a Colorbond fence. Frenergy has a large range of Hook Magnets.

When suspending objects from magnetic hooks on a Colorbond fence you should also factor in the effect of wind gusts and accidental bumps. These may help to disrupt or reduce the magnetic bond. Likewise, a painted or uneven surface where the magnet attaches to the fence will create a gap which will also reduce bond strength. A trial and error test is advised for this type of application.

Magnet Product Questions

Do you offer a discount for bulk purchases?

Frenergy attempts to give our customers the best prices available on Neodymium magnets at all times. Although the website already has tier pricing for each individual product you can contact the office for any special orders or unusually large quantity orders.

The tiered pricing for each product on the website is based on quantity. It is automatically calculated and applied to your order total at the website payment and checkout page. If you require the price and availability of any of our products you can email the office and get a prompt response. We do our best to respond within 24 hours.

Please note that steep upward trends in the price of Rare Earth minerals are expected to continue in the short to medium term. The high demand from emerging technologies as well as restrictions on production and availability from suppliers has meant Neodymium product values are soaring. Frenergy makes every effort to absorb these price increases for our customers wherever possible but many of the factors influencing current prices, including supply restrictions, quota limits and foreign government policies, are entirely beyond our control.

Is it possible to get custom magnets and how long does it take?

Global supply chains and logistics have been hugely impacted by the worldwide pandemic over recent years. Subsequent delays in production and the reduced frequency of transport routes have led to great uncertainty for manufacturers, retailers and consumers in every field. The pre-pandemic lead times for Neodymium orders were consistently around 8 weeks. The current (May 2022) lead time for custom order magnets from our manufacturers is around 12 to 16 weeks.

An order of at least $1000 AUD is necessary to commence production of non-stock magnets. Larger order numbers will attract a lower unit price but international shipping costs will be additional to the cost of production. Further to these already unfavourable circumstances is the issue of price and availability. Overseas manufacturers of rare earth magnetic products have had production quotas reduced while the price of raw materials for Neodymium products has escalated to record levels.

Frenergy will always try and keep prices as low as possible for our customers but recent market conditions, global fuel costs and scarce resources are proving to be extremely challenging in this regard.

Can you suggest any good quality bonding product to use on magnets?

A two-part epoxy glue has proven to be a very effective way to attach Neodymium magnets. Prepare both the magnet and the other surface by thoroughly cleaning both surfaces prior to use.

Glues like brand name builders glue or super glue are practical options for gluing magnets in position. Hard, non-porous surfaces are best for attaching magnets. Timber, composite and uneven surfaces will result in a less effective bond to the magnet. If gluing magnets to a surface is not an appropriate option for your application you may wish to use our Pot Magnets products.

Pot magnets have a steel cover that protects the magnet from damage, increases the holding strength and also makes it possible to attach the magnet to another surface with a screw, bolt, or nut.

What are Magnetic Sheets used for? Can they produce a magnetic field, similar to rigid magnets?

Magnetic sheets have the flexibility of paper and cardboard products and can be used in the same type of applications but can attach magnetically to steel surfaces.

The magnetic sheet material contains a mix of rubber and powdered Ferrite magnetic matter that allows the sheet to remain flexible. The thin sheets have only a moderate bond but this makes the sheets easy to remove and reapply to steel surfaces when needed. Typical applications for magnetic sheeting are promotional advertising products like fridge magnets and printed vehicle signage.

The magnetic sheets are generally less than 1mm thick. The thin flexible nature of the sheets and the high rubber content means these magnetic sheet products have far less magnetic power than thicker, non-flexible magnets. Most of the Frenergy White Sheet magnets are 620mm wide and sold in lengths of 1 metre.

We also have a range of Coloured Sheet magnets in 10-metre rolls. You can find various other magnetic sheet products for office printing, warehouse labelling and commercial printing in Frenergy’s Flexible Magnetic Rubber category.

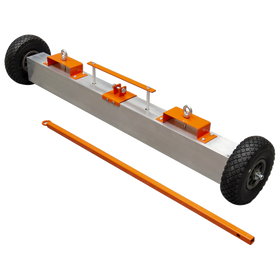

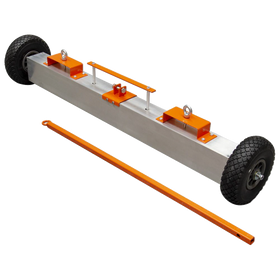

How do I decide which swarf cleaner model would be best for us?

Wider magnetic sweepers cover more area and are more efficient in large open workshop environments and outdoor areas. The Frenergy Tools and Equipment category has 72-inch wide sweeper magnets. These are the widest models available and can be attached to the workshop forklift tynes to make the swarf removal process a whole lot easier.

Industrial sites or workshop areas with more confined workspaces may require a smaller sweeper that can more easily access floors between workbenches or machinery. Frenergy also has several walk-behind, handheld Heavy Duty Sweeper models that are fitted with wheels and are available in sizes up to 60 inches wide.

These products have a quick-release lever that allows the collected swarf to be deposited safely into a container without needing to handle the potentially harmful swarf material.

The Forklift Sweeper category has 3 in 1 magnetic sweepers that can be hung from a vehicle, towed behind a vehicle or mounted onto the front of a forklift. Regular magnetic sweeping helps to make workplace safety a priority and significantly reduces the occurrence of those frustrating flat tyres for your staff and customer vehicles.

Are your magnetic sheets inkjet printable?

Browse the White Sheet Magnet category where you can find A4 printable magnetic sheets in a range of thicknesses that are suitable for home printers. Frenergy has A4 size magnetic paper with a matte or gloss white PVC coating. These can be used to make magnetic signs. The matte finish paper is thin and works best in an ordinary office printer while the gloss paper will require a commercial printing machine.

We also have A4 magnetic sheets with adhesive on the non-magnetic side which you can attach to your standard paper sign so it becomes magnetic. We advise you to first make a test print with the magnetic paper to make sure it is compatible with your particular printer before ordering any large quantities.

Other useful products include 620mm, 1000mm and 1200mm wide sheets in one metre lengths or longer rolls. Flexible Steel rolls with adhesive backing are also available from Frenergy. These steel-based sheets are ideal for making DIY wall-mounted magnetic whiteboards or steel display surfaces for magnetic items only.

Is it possible to get a double sided magnetic strip?

Most regular flexible magnetic sheeting and precut magnetic strips have only one side that is magnetic. They can be written on with a whiteboard marker and then wiped clean and reused. Only the dark coloured, non-writable side is magnetic.

Frenergy also has one flexible magnetic sheet product that is magnetic on both sides. The double-sided magnetic sheet is 1m long and 620mm wide. The 0.5mm thick sheet is easily cut with scissors to any size you require, so making a thin, double-sided strip is simple. These double-sided magnetic sheets are white on one side and can retain magnetic pins or flexible labels while also providing a white surface to write onto. The other side is dark coloured and will bond to any steel or metal surface. This double-sided flexible sheet is also available in brown colour.

Is magnetic tape strong enough to connect Perspex to a window?

Frenergy has stronger magnetic tape products that are ideal for this type of application.

Applying Perspex or acrylic double glazing to your windows is a sure way to improve the insulation of your home and save money on energy bills. The process is simple with Frengery’s Magnetic Rolls.

These matched pairs of flexible magnetic tape products include the popular Magnafix tape system. The flexible Magnafix magnetic tapes have adhesive on the back and paired A and B magnetic poles on the magnetic side of each tape.

Installation is easy. Cut the tapes to match the size of your window frame. Apply Part A to your fixed window frame with the adhesive backing. Cut and apply Part B to your perspex glazing with the adhesive backing. Be sure to prepare the surfaces by cleaning both sides to help maximise the adhesive bond.

Once in place and the adhesive backing has cured, the two parts will magnetically bond to each other exactly. Magnetically fitting your window glazing in this way makes it easy to remove the glazing for cleaning or when window access is needed.

Frenergy has these tapes in 12.5mm or 25mm wide rolls. You can also choose from the standard 3M adhesive backing or the Tesa adhesive backing which is more durable for outdoor use. The 3M 12.5mm tapes (59063A and B) can also be purchased in one metre lengths.

Does Magnetic Tape stick to itself?

Frenergy has Magnafix flexible tape which can be found in the Magnetic Roll category. These adhesive-backed paired tape systems are sold in matching A and B pairs that align with the North and South poles binding to each other.

Lightweight items like posters and photographs can be easily held with this product which has been designed to support far heavier objects such as lighboxes and perspex sheets.

Other types of flexible magnets are not designed to be used to magnetically adhere to themselves and would only provide a very weak magnitism. However small adhesive-backed Patch Magnets would be ideal to attach posters to a fridge or other metal surfaces. Pin Magnets will also easily hold your poster or artwork to a metal surface.

Please note: Attaching flexible tape magnets with self adhesive to non-metallic walls may cause some damage to the wall surface or paint when the time comes to remove the magnet.

I only have a small budget. Can I still get custom magnets made?

Due to the global pandemic conditions and the disruption this has caused to manufacturing and logistics in most countries, the cost of all magnetic products, including custom magnets has greatly increased. Minimum order quantities (MOQ) apply to custom made magnets to cover the cost of the tooling needed for products that are not in high demand. These custom order products will require an initial outlay of at least $1000 AUD plus the shipping costs from our overseas manufacturer.

For customers who have a limited budget, we recommend making some type of adaption or compromise to your magnetic requirements by using one of Frenergy’s stock magnet items. Consider using a stock magnet option with close or similar dimensions or perhaps combining two magnets to create the magnetic force that is needed for your project.

Spend $50 online to purchase some magnets with similar dimensions and receive free standard shipping. You can then trial them in your application. You can also, consider using a smaller magnet with higher N52 grade Neodymium to compensate for any loss of strength.

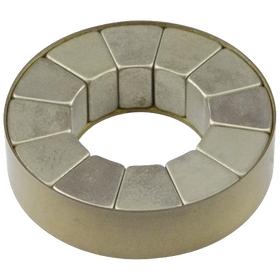

I am looking for multipole, diametrically magnetised ring magnets. Do you have anything like this in stock?

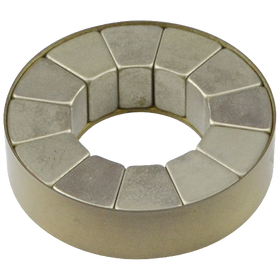

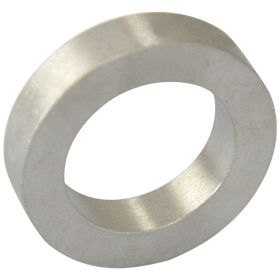

On rare occasions when highly specialised projects require them, a magnet with uncommon magnetisation properties may need to be sourced or custom made. Diametrically magnetised magnets have the North and South poles on opposite sides of the width dimension instead of the more usual height dimension (axially magnetised).

Most common applications use regular magnets with an Axial direction of magnetisation and this is how the majority of Frenergy’s stock is manufactured. This Axial type of magnetisation occurs during production in the factory. Frenergy has a small number of diametrically magnetised products in our catalogue in the form of Neodymium blocks and ring-shaped magnets.

Multipole magnets are also uncommon and are mainly used in highly specialised applications. This type of magnetisation is usually applied to circular Ring magnets or Disc-shaped magnets. The alternating North then South poles are located on the curved, outer perimeter of the round magnet. This circular multipole arrangement is sometimes known as a Radial direction of magnetisation.

If you require a magnet with special magnetisation properties you can email the Frenergy office with your detailed specifications for a free quote. Minimum order quantities naturally apply to special custom-made magnets and lead times in the current global climate can be 12 weeks or more. Frenergy has extensive experience in supplying custom magnet orders to customers in various fields and industries. Please don't hesitate to contact the office for any advice you need.

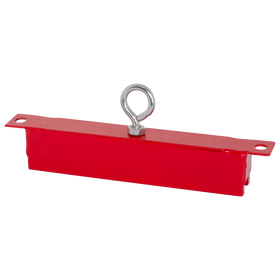

What are the functional differences between the PML and PMLR lifters?

One Lifter model (PML) is designed to lift flat sheet metal and the other Pipe Lifter model (PMLR) makes it possible to lift round steel products such as steel pipes and tubes.

The standard PML models have a completely flat attaching surface that ensures strong attachment across the entire magnetic surface. This strong and direct bond produces a higher weight lifting capacity for flat steel products.

In contrast, the PMLR model has a more angled contact surface which enables it to bond more securely and more effectively with round-shaped steel because of the more suitable contact surface area. Please note that the lifting capacity of the PMLR model halves when lifting round steel products.

Frenergy has Permanent Magnet Lifters available in a range of sizes and lifting capacities. One of the benefits of both the PML and PMLR models is that they have the handy, manually operated release lever. The lever disengages the magnet and releases the steel product safely once it is in the right location. This reduces the need for traditional slow and awkward block and tackle hoisting.

Direct contact between the Lifter and the steel is crucial to the performance of all Magnetic Lifters and any gap that results from paint, coverings or wrapping of the steel will significantly reduce the magnet’s lifting capacity. Frenergy has a range of magnets that can really to improve safety and productivity levels in your workshop or factory. Visit the Magnetic Tools & Equipment category to find out more!

Shipping and Returns Questions

Is it possible to pick up purchased items?

Free Pickup is available from the Rozelle warehouse for online orders only.

Online orders from the Frenergy website can be picked up by customers at the Sydney warehouse dock during weekday business hours before 3pm. Click on the Local Pickup option at the checkout to save on freight costs and collect your order in person or arrange your own courier to collect your items.

Alternatively, orders placed and paid for by 1.30pm each business day will be dispatched the same day. You can also choose fast shipping options (at additional cost) for urgent orders to anywhere in Australia. Get free standard shipping Australia wide for all online orders over $50.

See the Frenergy Terms & Conditions page for all the information regarding Shipping, Returns and International orders.

Do you have a shop front I could visit?

Frenergy does not have a storefront or retail outlet that is open to the public. Frenergy operates as an online store only and we ship our range of magnetic products to anywhere in Australia from our Sydney warehouse.

Online orders placed before 1.30pm Monday to Friday are dispatched the same day so customers receive their goods as soon as possible. Orders that need to be picked up take around two hours to process and can then be collected from the warehouse dock before 3pm that day. Customers need to place their orders online and then choose a delivery option and payment method at the checkout page.

Contact the staff at the Frenergy office for helpful advice about which magnet or product category is most suitable for your project or application. You can also browse through other sections of the Frenergy FAQ pages to gain more insight into our magnet range and their various real-world applications.

Free Standard Delivery Australia Wide On Orders Over $50. Find out about Shipping and Returns here.

What is your returns policy?

If you are not entirely satisfied with your purchase, we're here to help.

We have a 30 Day Returns policy at Frenergy Magnets. You may return your item within 30 days of receiving it to receive a refund. The product/s must be unused and in the same condition you received them in. Please contact us at info@frenergy.com.au to initiate the returns process. The buyer is responsible for the cost of returning the order.

Please send the items you are returning, with a copy of the invoice, to:

Frenergy Magnets

Unit 13, 5 Parsons Street

Rozelle, NSW, 2039

Australia

If you have received a damaged, faulty or incorrectly delivered item, please notify us immediately for assistance. Should your order be damaged in transit we will send a replacement, free of charge.

In the rare event of a website glitch displaying the incorrect price of any products, we reserve the right to cancel and refund any affected orders at our discretion.

If you have any questions about our Returns and Refunds Policy, please contact us at info@frenergy.com.au.

Terms and Conditions

If the product supplied is not identical to that which was ordered simply return the items in a new and unused condition in original carton within 30 days. Frenergy will replace the returned item free of charge including postage and handling charges or we will offer a full refund excluding original postage and handling charges.

Frenergy will not be responsible for any damage to a purchased product resulting from improper use or handling. Please read the "Magnet Care" section of our website for correct handling and use of you magnets.

No Warranty of any kind, expressed or implied, is made regarding the safety of the products sold. Buyer assumes all risks and liability from use of said products.

You may return most new, unopened items within 30 days of delivery for a full refund. We'll also pay the return shipping costs if the return is a result of our error (you received an incorrect or defective item, etc.).

You should expect to receive your refund within four weeks of giving your package to the return shipper, however, in many cases you will receive a refund more quickly. This time period includes the transit time for us to receive your return from the shipper (5 to 10 business days), the time it takes us to process your return once we receive it (3 to 5 business days).

Faulty Items: All products are individually inspected before being dispatched, to ensure items are sent out in perfect condition. In the unlikely event that a product is faulty, please return it to us within 30 days of receipt in its original condition. We can spot the difference between a faulty item and a mishandled item, so please be careful when using the magnets and don't let them smash together, IT WILL CHIP AND BREAK THEM.

Shipping

We can ship to virtually any address in the world. Note that there are restrictions on some products, and some products cannot be shipped to international destinations.

When you place an order, we will estimate shipping and delivery dates for you based on the availability of your items and the shipping options you choose. Depending on the shipping provider you choose, shipping date estimates may appear on the shipping quotes page.

Please also note that the shipping rates for many items we sell are weight-based. The weight of any such item can be found on its detail page. To reflect the policies of the shipping companies we use, all weights will be rounded up to the next full dollar.

Out of Stock: In the rare event that we become out of stock of a particular item. We will offer you your money back and an apology, or offer you a similar replacement product that you agree to, or if you don't mind waiting we will reorder the item and send to you in a few weeks depending on supply timeframe.

Postage Fees: We try to make sure the postage costs are fair, and cover the expenses necessary to get your product to you. Please only purchase an item if you are happy with the quoted postage. The postage rates are based on item weights using the Australia Post rates. Many of our magnets need to be carefully wrapped so we can post them legally through the Australia Post mail service. We don't profit from postage. If you require extra security for your items such as express post, registered post or courier tracking please inform us and we can add these costs to your order. If you do not request and pay for the additional postal security, we are not responsible for items lost in the post, held by customs, stolen, or any other incident resulting in you not receiving your items. We can also offer postal insurance however you will need to contact us for the cost of this additional service.

We reserve the right not to ship to remote or rural locations, if payment has been made a full refund will be given.

International orders: 2-3 weeks (by regular airmail). Please check your country's import tax charges, duties, and fees. We are not responsible for these charges.

Delivery Times: Orders are shipped within 1-2 days of order unless backorder of out of stock item.

- Australian Domestic orders: East Coast, Central take 3-5 business days and West Coast take 5 to 14 business days.

- International orders: Take 10-21 days depending on country. These time are not guaranteed.

- For EXPRESS POST: Express post orders placed before 1pm will be sent out on the same day. Orders placed after 1pm, will be sent on the next working day.

Purchase Currency: All payments are charged in Australian dollars, International Customers may receive conversion charges, please check with your bank.

GST Information: Product prices are quoted in Australian Dollars (AUD) and include Australian GST

** Australian Goods and Services Tax (GST) of 10% is charged to Australian customers only on both products and shipping.

What are your delivery times?

International orders: 2-3 weeks (by regular airmail). Please check your country's import tax charges, duties, and fees. We are not responsible for these charges.

Delivery Times: Orders are shipped within 1-2 days of order unless backorder of out of stock item.

- Australian Domestic orders: East Coast, Central take 3-5 business days and West Coast take 5 to 14 business days.

- International orders: Take 10-21 days depending on country. These time are not guaranteed.

- For EXPRESS POST: Express post orders placed before 1pm will be sent out on the same day. Orders placed after 1pm, will be sent on the next working day.